Harley Specialty Tools

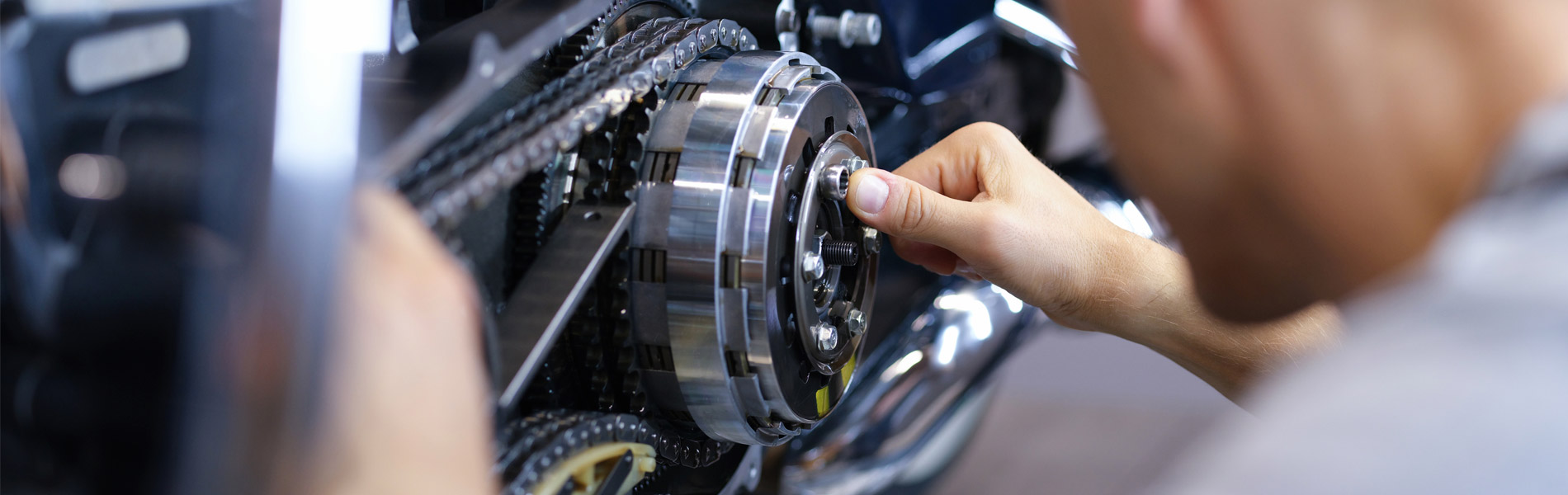

Bob LaRosaWhen you hear specialty tools you may think of a $200 tool that you may only use once or twice. In this video we walk through some tools that will make Harley Davidson maintenance and performance upgrades a lot easier.

I want to discuss something that everyone, no matter if you've just started turning a wrench on your motorcycle or you've been doing it for years, you're going to need to acquire specialty tools. When I say specialty tools I don't necessarily mean a Jim's brand or George brand specialty socket or retainer. I'm talking about ratchets or instruments like a torque wrench that you're needed for a special application. One of the most important tools in my arsenal is the flashlight. I carry a small one with me all the time.

You never know when you're going to need to illuminate an area you're working on. Whether it's a problem that just arose or you're just trying to look around for something you might've lost, or while you're cleaning you want to make sure you clean in a dark area, on your motorcycle, under the hood of your car. Flashlights are a necessity. I try to keep one in the garage with fresh batteries in it. Like I said, I carry one with me, a small one.

When it comes to ratchets, don't take for granted that you have enough ratchets. They make a number of configurations, whether they're long handled to reduce leverage when you're breaking a bolt loose, or their swivel style. This allows you greater access to a number of areas that you normally can't reach with a fixed-head ratchet. They also make one that I use constantly that allows me to pivot the head of the ratchet 360 degrees. What this does, it enables me to get into areas with the head of the ratchet that you normally couldn't get into.

Adapters, whether you need to get from 1/2 inch to 3/4, from 3/4 to 1/2, from 1/2 to 3/8, 3/8 to 1/2, 1/4 to 3/8, or 3/8 to 1/4, you need a special adapter. Make sure you purchase them. Again, I can't stress enough, purchase high quality tools. I would rather have two high-quality tools than a dozen low-quality tools that may fail when I depend on them the most. Another thing you will need with today's vehicles, motorcycles, motor sports, or automobiles are going to be Torx and Allens.

They are available in a short or a long configuration. The Allens themselves in a long or short configuration are also available with what they call a ball end. This ball end gives you a certain angle out of the top of the hardware. Not necessarily the best way to tighten it but when it comes to sneaking in a tight spot like a starter bolt motor under the oil tank into the inner primary, a ball Allen and a wobble extension become invaluable. When it comes to extensions they do make a number of lengths.

They make a number of configurations whether it be smooth body style or neural. So you can grab them with your fingers. The wobble extension allows the socket a little bit of movement that you just don't get on a fixed extension. And that little bit of movement may be the difference between accessing a piece of hardware, completing the job correctly or not. Again, not in the tool category so to say, but a definite instrument of your tool arsenal are torque wrenches, inch pounds and foot pounds.

Make sure you know the difference when you're torquing hardware. If you torque a component that should be torqued to foot pounds to inch pounds, chances are it's way too loose. If you try to torque a component that should be inch pounds to foot pounds, the chances are you're just gonna snap it off before you even hear the torque wrench click. Another very helpful tool are ratchet-style wrenches. These wrenches allow you to work in very close quarters tightening and loosening things without worrying about getting the wrench caught or not being able to move it enough to tighten or loosen a piece of hardware.

Needle-nose pliers, vice grips, channel locks, all pliers are important. They're meant to grab things. The hands are meant to hold tools. The hands are not tools. So if you're in the habit of twisting things and forcing things in place by hand, get in the habit of using the proper tool.

You'll find the end result is much more correct and it's much easier once you learn to use the proper tool for the proper application. Of course there are specialty tools, belt gauge, belt tension gauges, sprocket locks, drive lock tools. There's a handful of specialty, what we call dog bone style tools and adapters. Of course there are your specialty tools for removing, reinstalling races, seals, and bearings. An important kit that is in my toolbox are tweezers.

Now you never know if you need to grab something that's just out of reach, tweezers work very well in that application. And then again, it may come down to a something as simple as picking up a sliver. Whether it be wood or steel, you want to be able to grab it, remove it out of your skin, or a person you may be working with's skin before it gets too deeply embedded and you need to seek medical assistance. Another pet peeve of mine is electrical tape, masking tape, scotch tape, any type of tape. If you're installing it onto something, make sure it's wound very tight.

Make sure it's going to serve its purpose. When you're done, just don't rip it away, leave a jagged end, stretch the tape out to where it won't adhere to itself. Always start and stop with a nice clean-cut edge when it comes to tape. If you start with a clean edge, you can wrap the tape around the component you're trying to hold together or seal out from the elements. And when you cut it clean, you don't stress the tape causing it to stretch and wanna come undone.

Once the tape has been touched you can try to stick it to itself. It's not gonna adhere very well. The same applies with masking tape, two-sided tape. Again, a tool that has to be in your first aid kit has to be in your tool box, but doesn't necessarily be used- but isn't necessarily used one for the other. I wouldn't use a set of scissors that I cut fuel line hose for in my first aid kit.

Buy a couple pairs. Buy a few different styles. Use what you're able to use, what you're able to afford. Use what you're comfortable with for the job.

Share tips, start a discussion or ask other students a question. If you have a question for an expert, please click here.

Already a member? Sign in

No Responses to “Harley Specialty Tools”