Harley Six Speed Transmission Rebuild - Part 3

Mike RoenThe Harley six speed transmission is on the workbench for disassembly, cleaning, and inspection.

Door Bearings

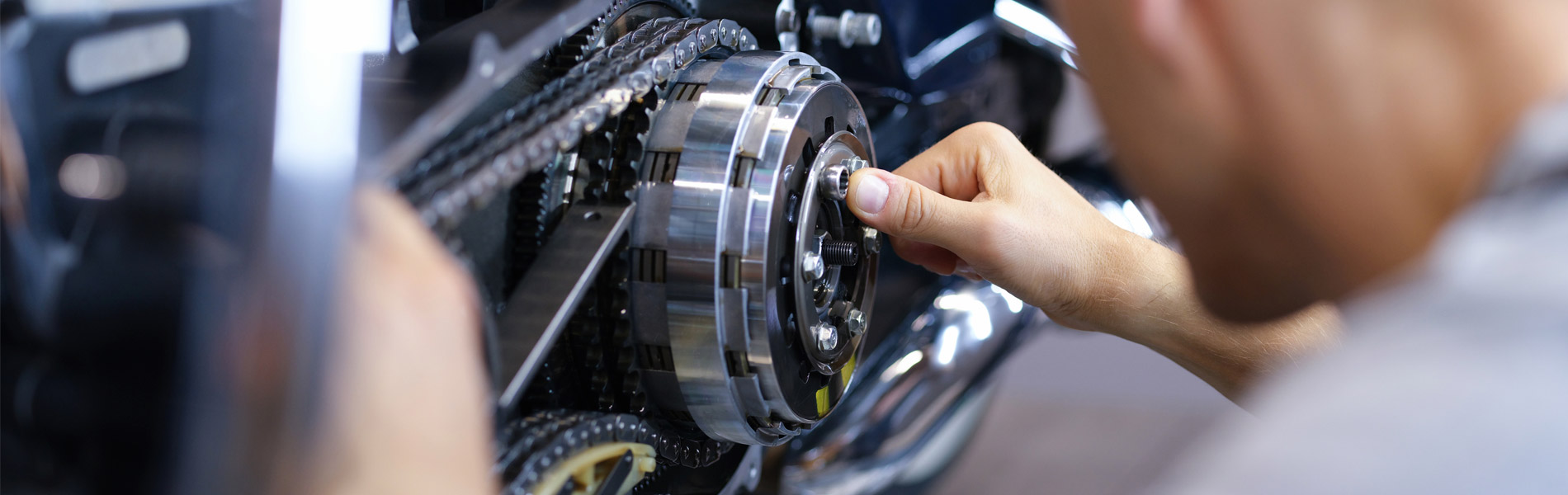

With the Harley six speed transmission door cleaned, we can press two new bearings into place. Be sure to correctly support the aluminum door and only press on the outer race of the bearings. Doing otherwise can compromise or render the component useless. Reinstall the bearing retaining clips with the flat side down (against the bearing) and the bevel side facing away from the bearing. Verify that the clips are correctly seated.

Harley Six Speed Part Assemblies

Disassemble, clean, and lay out the the mainshaft and countershaft assemblies. You should have your factory service manual opened as you move through a repair as involved as this. It is also very important to take photos, write down notes, and make reference markings on the Harley six speed components as they are being laid out.

The mainshaft is mainly one unit that includes gears first through fourth. There is also mainshaft fifth gear, and a dog ring on the shaft, but those are independent from the main cluster of gears. The main drive gear is pressed into the main drive gear bearing at the end. The countershaft fifth and sixth gears are also part of the countershaft. Countershaft first through fourth gears are independent, individual gears.

Replace All Bearings

Also, on both shafts, there are small bearings that reside inside any bearing that is considered to be a freewheeling bearing. These bearings should be replaced along with the securing segments and the lock rings.

Back To The Press

When the Harley six speed mainshaft and countershaft assemblies have been disassemble, inspected, cleaned and reassembled, they can be pressed back into the transmission trap door bearings. The countershaft needs to be pressed in first. It is of utmost importance that everything is correctly supported as specified by your service manual. Mike gives us a detailed demonstration of this.

After both shafts have been correctly pressed into position, temporarily slide the gearset back into the case so that the shaft lock nuts can be properly torqued to factory spec. Reinstall the detent assembly with a new, factory bolt. Reinstall shift forks and tap the shafts back into their previous positions, then reinstall the shift drum and retainer with new hardware.

Next we will dry shift the transmission and get ready to remove the main drive gear.