Harley M8 Cam Removal Continued

Mike RoenMike has the pushrods and the Harley M8 cam cover removed and is ready to move on with disassembly for our S&S cam upgrade.

Next in line are the front and rear lifter covers. A 3/16" Allen is needed to remove the securing hardware. A wobble, or ball Allen will be needed in order to access and remove the inner screws. As Mike notes, Harley uses Loctite on these screws. They can be difficult to remove without stripping the heads of the screws. If a screw becomes difficult to remove, use penetrating oil. It is also helpful to work the screw in and out (clockwise & counterclockwise). Heat can also be used as a last resort.

The lifter guides are next in line to be removed. There is a single bolt for each guide. These bolts are also known to be difficult to remove cleanly. A 3/8" six point socket is used on the hex heads. Again, practicing patience can save a lot of time and aggravation going forward. If you break one of these bolts or pull aluminum threads from the crankcase, you will end up spending time making a repair before moving ahead with the upgrade.

The lifters are now removed from the crankcase and set aside. They will not be reused for this upgrade. However, if lifters are to be reused for your application, it is of utmost importance that they are returned to the same location and that the roller bearings spin in the same direction.

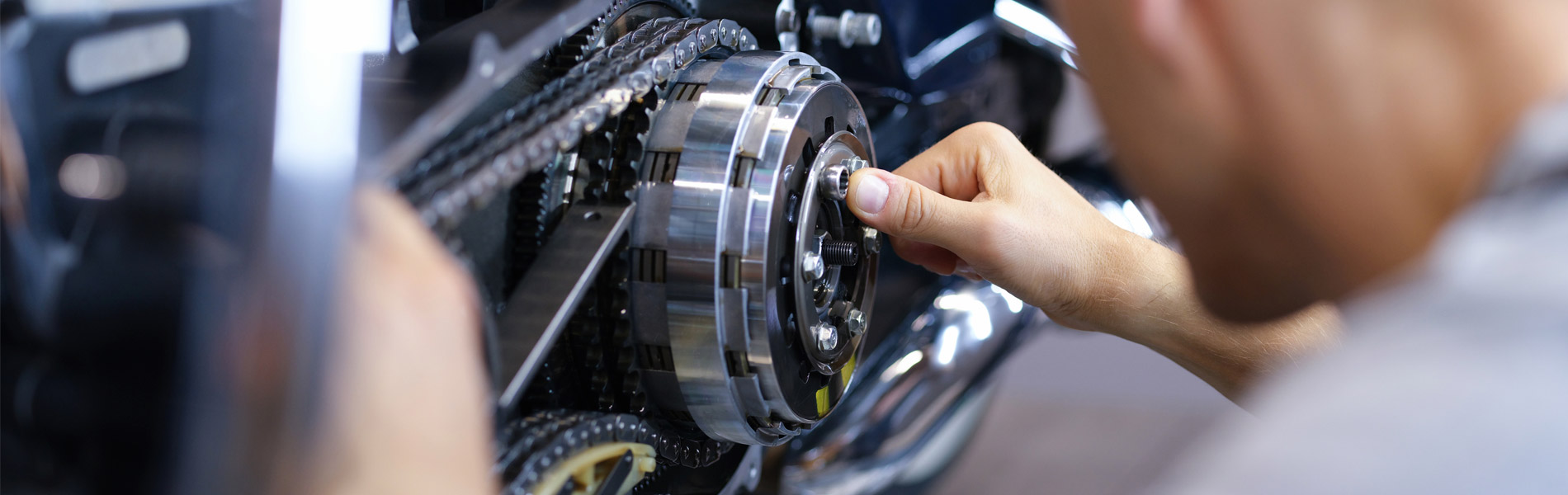

Mike removes the Harley M8 cam chain tensioner with a T-27 torx bit. Then, a gear locking tool is used to hold the cam and crank gear while their retaining bolts are removed. Take a minute to mark the timing chain before removal. It is important to keep it spinning in the same direction.

Mike removes the cam gear, the crank gear, the timing chain, and the cam gear spacer.

A 3/16" Allen is used to remove the Harley M8 cam plate and oil pump hardware. Mike removes the M8 cam plate exposing the single cam and the oil pump. Finally, the camshaft and the oil pump assembly are removed.

Mike will now clean up a little bit. Next up, he will show us how to measure the crankshaft run-out.