Harley Compensator Upgrade

Bob LaRosaDoes Your Harley Compensator Clunk?

We were excited to get our hands on this Harley compensator upgrade from Baker. Riders have been dealing with Harley’s poor compensator design for some years now. Even their Screamin Eagle upgrade turned out to be an inadequate solution for most. Some riders actually spent a lot of money to buy a new Harley-Davidson. They had to deal with clunking, loosening Harley compensator, and starting issues. They may have spent more good money for the Screamin Eagle upgrade (as well as labor costs) only to still have the same issues eventually redevelop.

The Noise

The noise can be heard in the primary drive when you shut the engine off. The noise occurs when the factory Harley compensator returns to its lowest position. The design flaw is lack of lubrication within the assembly and the clunking or banging that can be heard verifies that excessive wear is occurring at the assembly.

A Solution

Baker has now given us an assembly that permanently solves this problem for Harley Davidson motorcycles 2007 and newer. Baker has borrowed from the tried and true pre-2007 cam lobe geometry but has added modifications to the motor shaft extension and developed a Harley compensator sprocket and spring cup that have oil passages in them, allowing for plenty of oil to lubricate the compensator’s cam lobes. The Baker design not only eliminates clunking but also improves function and adds extended durability over the stock, flawed, factory design.

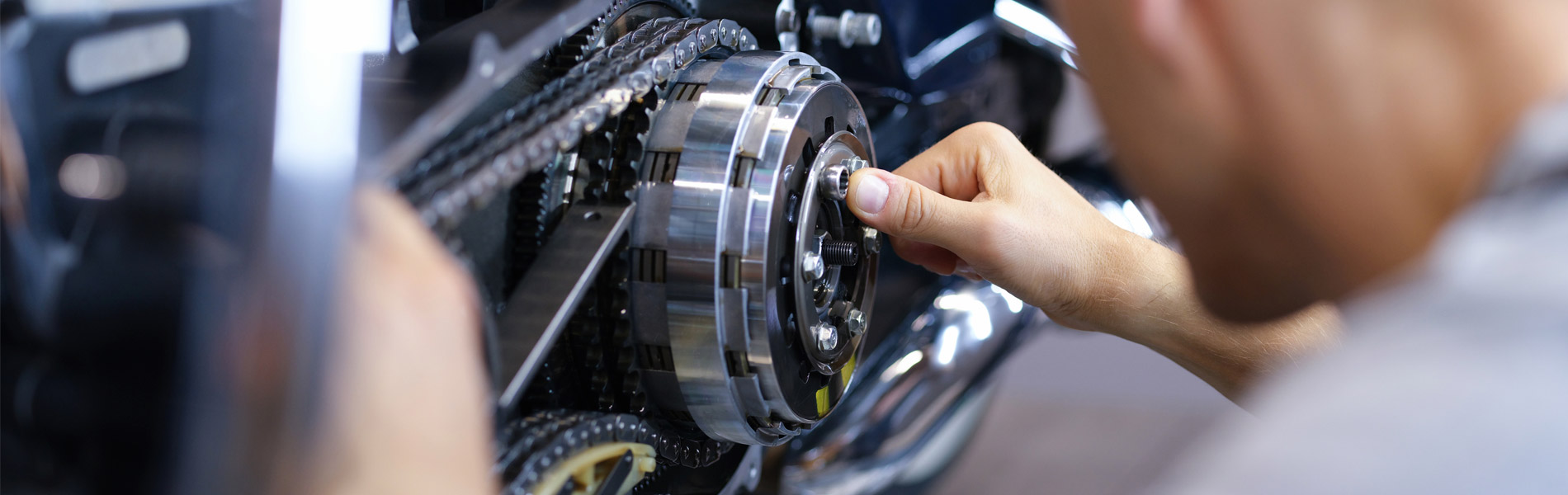

The assembly is sold as a complete kit. It includes an engine extension shaft, a 34 tooth compensating sprocket, cam slider, spring cup assembly, and a hardened 9/16-12 hardened hex bolt. The only other parts needed are: outer primary gasket, derby cover gasket and (40-45 oz) primary drive oil. Both, Baker and Fix My Hog recommend using Spectro primary drive oil. The instructions are very straightforward. Provided the correct tools are available, we consider this upgrade to be easily achievable for the "weekend mechanic".

Hi, I'm Bob LaRosa. Welcome to Fix my hog. If you happen to own a pre 2007 motorcycle, this upgrade will not apply. If you're one of the fortunate ones like I am who own a 2007 and newer model, you may be, chances are great. You may be encountering some type of clunking noise in your drive.

When you shut your motorcycle off, what you're hearing is the new style compensated assembly coming to rest at its lowest position problem with that is it's not oiled well enough when it relaxes that it makes a clunking or a banging sound. Any type of banging or clunking sound, we all know is causing excessive wear. Baker has come up with a cure to the 2007 and newer compensating sprocket noise. This setup uses some of the basic geometry from the pre 2007 and older compensating setups with a bunch of patent pending design changes including these grooves. You see here that allow extra oil into the compensating assembly.

It'll pretty much alleviate and eliminate all of the clunking and banging sounds. Baker, drive train markets and sells this as a complete kit, you walk up, you drain your fluid, you remove the outer primary cover, you address just the compensating sprocket assembly as a unit, put everything back together, your noise is gone. The weir factor is eliminated and you're guaranteed that the compensating assembly is getting well oiled and operating correctly each and every time you ride.

I have a 2016 Heritage Softail that I took in for the 15,000 mile service. I am the original owner of bike and the Primary Compensator needed replaced. The bike unfurnished out of extended warranty. I am very upset that HD knows there is an issue and didn’t have a recall to replace the poorly designed compensator. Makes me want to trade for an Indian ....

I have a moderately modified 1999 80ci softtail turned trike with a VG chain rearend.

Why can't I see the video

Had Baker comp fitted to my 2010 FLH Road King, along with Baker 7 speed transmission. Best add on ever. No more clunkuing and hardeto find gears including neutral. All gear changes smooth and clean and quiet. No false neutrals. and no clutch slipping in fifth gear. Thyis is actually a gear box fault but HD and dealers will not admit to it.

I just bought a 1989 FLHTC , EVO 80 CI , do I need this up-grade ??

Installed SE comp about 4 years/40k miles ago. Took a dump this past summer. Installed new SE comp in fall, now have slight clunking when idle goes below 1K (worse cold). Bike seems to perform ok otherwise, noise goes away when rpm is raised even a little, still have some hot start issues but not nearly as bad as was with first SE comp (after it wore out).