FMH LIVE: Gauges – Info and Troubleshooting

Tommy CrealIf you’re running into constant headaches with the mess of wires in the inner fairings electronics, then join Tommy 'Clutch' Creal to learn a bit more around how to troubleshoot those pains. With a typical aftermarket 6 gauge, Tommy demonstrates how to properly wire/troubleshoot the gauges, covering additional stereo system upgrades, diagnosing ABS Hydraulic Unit malfunctions, gas level gauge and more.

Related Videos:

Harley Key FOB

Fairing Removal and Custom Gauges including Oil Temp Gauge

Custom Gauges / Wiring

Handlebars & Wiring

How to Install LED Lights for Your Harley-Davidson

Electrical Systems

And Search for all related topics with the Search Box

Feel free to ask questions live during the show by using the chat box below.

Hey guys, welcome to this month's Fix My Hog event, I'm Tommy Creal, a contributing editor with Fix My Hog. And last month we kind of went over a few things with the stereo system. And a few of the electrical components in there. And this month, we're gonna go a little bit more in depth on helping you guys troubleshoot some of the items that you may see going wrong with your gauges, your headlamp, turn signals, all that fun stuff with wiring. So stick with me in here for the next hour.

And you're gonna learn a few tips and tricks along the way, and able to diagnose a lot of these problems just in your own garage at home. So before we get into things, I wanna mention two things. We've got this wicked chat roll going up on, fixmyhog.com. We've got to pull it up right here. So if you guys see anything or have questions along the next hour, feel free to put them right here in the chat role.

I see a pop up, we'll get over to the questions and get them answered and hopefully get your problems solved for you. So again, that's fixmyhog.com and then just go into the videos for the live event. And you'll see it right in there. And then also, we've got a download available free of cost. It's six possible causes for our Harley Wobble.

You can find that right under the chat role, and you should see it right onto your screen right now. So it doesn't hurt to download that guy. All right, well the next hour, guys we're gonna be trucking through this front end. And I'm gonna give you a kind of outline and guide to what we did to this bike, what it is, and get into the fun nitty gritty of it. So what I've got right here is a 2011 Harley softail CDO.

And we actually went through the entire front end, removed it, and made it into a 2016 later Street Glide. So there's a different stance that you see right now than what originally was. Obviously there was no fairing on the outside and none of the fork cans. We replaced the the forks entirely. New rim, new wheel and the front fender and all that stuff.

But more so inside this fairing is what we did. And the reason why I picked this bike for this hour, is that you will not get a more complicated electrical outline or schematics worse than this one. And I see my guy over there shaking his head, because we spent numerous sleepless days trying to get this done. So this is an ideal bike for taking you through, because we had to rewire and kind of trick the data bus and computer inside of it to give us all our gauges. So hopefully you got all that.

And what we're gonna start with here, before anything with electrical, I'd like to mention, I'm sure many of you guys already know, to remove your main fuse or disconnect your battery. I already removed the main fuse. And if you have an alarm on your bike, just turn it to the run position and pull the fuse. If you have it in off position, it typically likes to blare and beat your eardrums out of your mind. So make sure you pull that guy out, it prevents any issues that we may see along the way with possibly ruin some of your components.

So, all right first things first. Anything we got, we always use one of these nice, pretty towels, making sure we're not gonna damage any of the paint that we are already have done. And I've already removed four of the screws on here. From the inside of the fairing. Two on either side down here and one down here below the headlight, going into our fairing kit right here.

So I'm gonna take these top three that we have up here, remove these, it should be started. And once we get this thing off, you'll see the nice little mess of electrical. And when I do any kind of work on bikes, and many of you guys may already do this, I remove all the watches or rings I may have on my fingers because there's been a few times where, you scratch the paint, and it's never a cheap bill to flip when you get that done. All right, we've got that thing removed, pull the windshield right out. And then, we've got this little Kuryakyn phone holder, that just goes right on the inside.

Remove that guy as well. So at this point, we've got, that rubber seal is, really holding this on. That's a good fit though. All right, it's a silicone. Come over here Zach, would you mind grabbing that side real quick?

Popping that off. There we go. Perfect. All right. And what you guys are seeing, why that was a little rough, was our rubber seal on the inside of the fairing right here.

We'll put a new one on. And get that pretty done. Yep, nope. So I didn't remove the headlight. Aware this is a 3 prong connector right there.

This is a custom bracket we did on the inside, to hold out this headlight trim. So you may need to customize some of that. All right, I'll get this back here. Now, here's all the fun stuff. So what we've got right here, this is our Dakota wireless antenna.

Last month, I actually went through with you guys and helped with some of the items you may see with a ton of reception, not working, working. I mentioned this, and this is a great upgrade for anybody, no matter what kind of style radio you have or stereo system. This thing really helps clarify your signal, no matter where you're at. And it's just as simple as mounting here with double-side 3M tape, and then just plug in directly into your deck. On this side, we've got a JL speaker and inside there's a tweeter.

We've got our gauges up here, Rockford Fosgate speaker right in this area. This is our battery volts gauge. Down here, we've got our gas level and the other side down here, we have our air, ambient air temperature. You'll see right here, crossovers. We have a bracket that was on here, so we must have changed it.

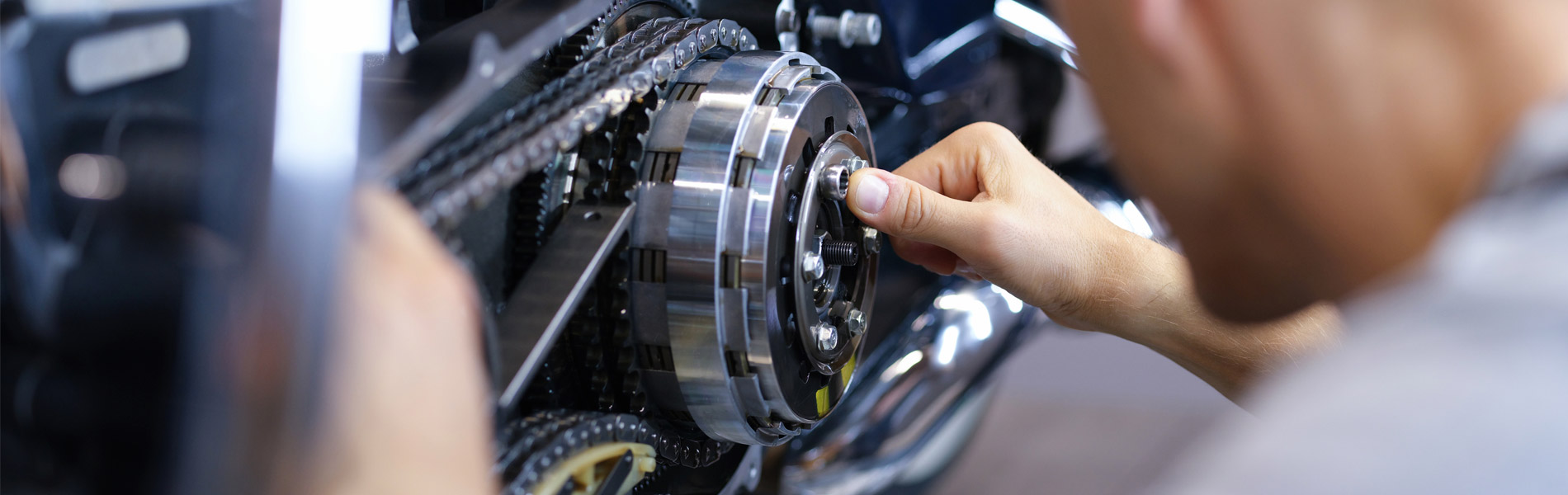

This is our ABS hydraulic unit, for our anti-lock braking system. Our amp right here, we custom made this little, bracket under here. And then you'll see just an accessory plug right here, cigarette, lighter, all for charging. And then the deck down here. Now, typically when doing a whole front end like this, there's probably about two wires or three wires that were initially run out here.

So everything that you see on here was added. All the speaker wires, all our wires for our Amp are running back. And we had to extend a few more. So today what we're gonna do, is go through the gauges right here. And how to upgrade your current Street Glide, Road Glide, Softail of any kind and what to look for.

And also some components with our ABS unit right here, troubleshooting that, and also our radio. So kind of diving right into things, with our six gauge setup. If you have an OEM, it's pretty easy and simple to pull these guys out. You'll have these wires going through, as you can see they're plugged in right here. They just connect to one another all the way through.

And what that is, is these are actually your dimmers. So you'll see a change, you know, depending on night or day. And these are just plug and play. It's really hard to get these wrong, I guess you could say. And then we're gonna do on your main gauge right here, you just plug and play again.

So if that is not working, one recommendation I can say, is make sure have the right plug. There are some plugs that have a nine pin, other ones with 12 pin. This one could be a hassle. So make sure it's all the way in there, that seal's pressed in tightly. And you will have another gauge here, with the same setup.

Push that plug all the in, and you're good to go. Now for a more in-depth look with these gauges, and if you can fly that camera in pretty quickly here, I've got one disassembled gauge right here. You can see the outside. This is where you're gonna see your plug, here's your dimmer. And then here's the inside of these Dakotas.

It's an expensive way to look inside too. So make sure, you kind of keep all these things intact. When installing these, you're gonna go from the inside of the you're inner fairing to the outside and you're gonna have a bracket. You'll have a seal around here, that you make sure that's on, that helps with any rain or water or debris getting in there to potentially ruin the gauge itself. And then this is just gonna pop on the back.

So it's gonna come right through, as you could see, hopefully right here a little bit. This is coming from the inside, this is coming from the back, and it pretty much pulls itself together, right in here. That's how your gauge is mount. And it's as simple as that. These gauges are, can be pretty expensive, but along the road, they typically last a lot longer than some of the OEMs and you have less trouble or issues with them along the way too.

So this is your typical setup. Remember just a ring here, bring it from the inside of the fender, bring this on over, and you're good to go. Plug in, plug and play that's about it with those guys. And then we have different kinda gauges. This is a temperature gauge right here.

We've got the gas gauge, like I said over here and oil pressure. Now a lot of these gauges, will have a pressure sensor or a module that's needed. That's helps with reading the sensor or reading the signal. So this is the oil pressure sensor gauge. And this goes down, right down at the bottom of the crank case.

And this is reading the oil pressure. Now when installing these, these can be a headache sometimes. Fortunately, we have a chin spoiler around there where we can help hide the wire, if we can't go inside the frame. Easily screw this right in. And you're gonna plug and play on the back end.

You'll see right here, we'll make a nice little terminal connector and put it right on there. And how this is split off, typically some of these sensors will allow you to connect intertwined with the other gauges that's just for here. So we'd actually have this one split off to another gauge. But it's pretty simple and straightforward with that. Make sure you get the right gauge or sensor.

The options are endless I should say with this. And then battery one is the easiest one, you'll put into play. Install that, run one ground, run one wire all the way back to your battery, and you're good to go. Additionally, with the ambient air temperature ones, those are ones that you need to actually having different modules. So what you see right here, this is a module for reading the air temperature and also the GPS that we have in, on the inside of here.

So that's an extra component we have to get. Otherwise, a lot of these gauges, we'll just plug and play for you. So that's it with the gauges and installation. You guys have any questions on those, please drop it in that chat role. Actually, I will mention one more thing.

This is a transmission speed sensor, and this goes all the way back to the top of your transmission. Inside of here is a shim, you may need it, you may not need it. When we drop this in, you know what, I'm gonna open this up so we can see it. May need it may not need it. But what it comes down to, this is the top right here and you'll see a seal.

If this goes down too far, it's gonna catch your gears. And that's obviously something you wanna avoid. So make sure that shim is put up. If you don't need the shim, put it all the way down your transmission, then run these wires all the way through. So that's something to keep an eye out for.

If you're pushing your bike and all of a sudden neutral is locking up after installing one of these, I would suggest to kind of run right back and look at this. When running these wires too, I can give you a whole ton of wire to run this through your backbone, under your gas tank. One of the items that I'll mention that you need to avoid is pinching or binding up that wire. I've seen, we've had bikes coming through the shop, they're running it through the backbone, up through the neck, and all of a sudden you'll see a wire right next to the neck and it's actually pinching with the triple tree. So if you can, with all your wiring coming from the back to the front and connecting those even in the front end, make sure there's nothing potentially binding or moving in there that can pinch those wires.

I mean, a little wire about this big will, fly up and smoke out your garage. So, and obviously go all the way back and ruin some of the fuses, break those and cause additional issues with other wires. So make sure pay attention to that and how you're routing these wires. All right. Now make sure we're on topic here with some of this stuff.

All right, another area that I wanna bring up, is with these gauges. We have a unique situation in this bike right here. We were given a one gauge set up with this and it's actually right here on the tank on the derby cover area. We milled this one out and chromed it and kind of sealed it off and put it up here in the front end. What we had to do, is we had to kind of trick the computer to work with all six gauges.

So with this main gauge, we plugged it in. And in there you have a red and white wire typically. They're intertwined all the way through. That's called your data bus wires. And that's transmitting all the information up here to your electronics.

Now, if you have a Road Glide, Street Glide, typically a softail, you can just buy the setup. Now with this one, we had to splice off and like I said, trick the computer into putting out different information, so we can pick up all these other gauges, as it was set for this one. And what I mean by that is, by plugging in here, we're actually gonna remove this. There's two prongs in either side to remove these. Come on, don't be stubborn, it's only Tuesday.

So back here, here's the plug. See all the heat shrink. But we ran two different looms out of here. One loom was telling us all the oil pressure and gas, that's gonna be over here. And then the other items are gonna be on this side.

So it's mandatory that you kinda take a look, at the schematics and what the... Oh, someone's calling. Take a look all the way through what you have, and make sure that you get that kinda nailed down and figure out what the issue is. Sorry, guys. And catch those, otherwise like I said, look through those schematics.

And a lot of times they'll have some of the issues with problem solving and troubleshooting the issues in the back end of that as well. So these are pretty nice set up, they look good. They have a ton of functions and options inside of here. In the inside of here, we're just working off of a single button on this side, that will tell us a speed, tax built in there. All the gauges are built in there.

So we duplicated them actually on this bike to make it work. And then you get all your trips and all that fun stuff. So with these gauges, look into them and like I said they're straightforward, I can't say that enough. Maybe I have, but they're pretty good. All right, I'm gonna check, see if any of you guys have questions yet.

I've got some that were already submitted for later on, but guys are doing good all right. Cool, you guys seem like you're set. All right, we're gonna move on to the radio. I think pretty much everyone has some sort of radio nowadays on their bike. And like I said, last month we went through a few things with the amp and speakers, crossovers.

And how to clarify and get your radio system pretty transparent, but we won't go too in depth, but just from a kind of a troubleshooting area with these. As you can see, we have this JL audio, we've got a 600 amp here and a six channel, or 600 watt and a six channel coming out of here. And we've got our JL's and crossover. So a lot of times with these and hooking them up, either someone has put regular wires in here, which will not let you get, the best signal coming out of there. So if you're upgrading yours, make sure you actually using speaker wires, same thing with your amp wires that are running out of here.

As you can see, we've got some heavy duty gauge rolling out of that power in the ground, going directly to the battery. And when we always run these all the way back, as you'll see on your OEM setups, there should be a fuse that actually goes right to the battery in between that setup. So if there's not, I would highly recommend putting that in there. And it just helps along the road, when you have to actually work on your radio or front end. And then there's a blue wire that we have here curled up.

Now we did this on a lot of bikes. When we run looms up to the front or the back, we'll always stretch a couple extra wires all the way through just in case we need to pull them. So what we did is we ran that wire all the way to the back for a rear. When we do the rear end of this, we've already got room and we can connect the amps to one another. Right in here, a lot of times when you're connecting your deck to your amp, these come loose.

They come out and all you gotta do is, push these right back in and make sure they're securely pushed in. Also another little tip, we sometimes put silicone around the side to hold it and that'll prevent anything from wobbling out or getting that kind of issue down the road. So make sure you take a peek at that. There's a question. So sometimes my entertainment system does not turn on, on a 2018 Street Glide.

All right. Yeah. All right so with your 2018 Street Glide, shouldn't be running tissues right off the bat on those. If your radio's not turning on, was that the question? It's entertainment system.

Okay, it's not turning on. A lot of times and I was gonna get to this a little bit later. A lot of times with the electrical components, it's either a bad ground, faulty wiring. If you've got an OEM setup and you haven't done any aftermarket work to it, my first recommendation would be taking off that fairing. And double-checking all your connections on the back of your pad.

And seeing that everything's secure. If you still have issues, you can actually run into the entertainment piece being faulty. So you'd contact Harley and make sure it's under warranty, but those are the two choices on there. A lot of times it's just a faulty plug or wire. So check on that.

Going a little bit more in depth on the, hopefully that helped by the way. Going a little bit more in depth on this, we've got our crossovers here. These were actually, double-sided taped up here, but we left enough wiring back here to go all the way through. As you can see to our other speaker back here. And we kept all these wires out of the way from anything moving, same thing with our inner brackets right here.

We use these as mounting points for most of the time. Our bracket that was used for this, the hydraulic ABS unit was mounted up here. And that just prevented anything from having issues. And when you're mounting a lot of these electrical pieces, if you go into doing some of the stuff by yourself, in your garage, big word of advice I can give you is to make sure that you're not gonna have any interference with your fairing. Early on when we were doing stereo systems and doing brackets like this for the amps, we would run into issues with different sized fairings not fitting.

The same thing ran into, when you're putting a lot of electrical components all over the place. Number one, you wanna make sure they have ventilation. And they're not getting too hot or else you're gonna run into those kinda issues. But obviously making sure they're out of way, for anything gonna be moving. So, as you can see there's not much coming out from here except for one loom.

There's crossover is down here. And we tried to avoiding everything. So we've got only two looms coming right back here with a nice wrap on there. And made sure those weren't gonna bind up. So same thing, make sure everything's kind of moved out of the way and you're not gonna run into those kind of issues.

All right, so our ABS unit, we're gonna get into this a little bit later more in depth on how these work and also how they should be functioning. 'Cause we've had a few in that, we're faulty to the point where the inside solenoid and the computer weren't reading right, so the valve wasn't opening and allowing the brake fluid to go through. And running that back it actually came back to the internals going haywire inside of here. And we've also had some where this little plug, these wires just come right out of the connectors. That's a lot of times what you'll run into too, is the wires make their way and start grooving out of there, and find a new home somewhere else.

So check on those. What else did we got in this thing? This thing was a lot more painful than it is talking about it, when we were putting it together. Simple accessory, cigarette socket, used for charging, whenever you need to. It's just a power in the ground going right into there, so just put in one single wire to that, rather than splicing one off.

A lot of times you wanna avoid splicing wires and drawing that kind of power out of one wire. It's nice to have your own, along the accessory circuit, your own wires coming out of there. And that's where this sucker is. Last thing too, is that we put this little Rockford Fosgate speaker in here. And that was too hard with the six gauge set up to really get everything working.

The computer gave us a little trouble for a few weeks. So we were able to get all the other gauges working, however, to have a speedo and tacho, it was just too much of a headache. So we put us a softail one, rewired everything again and got that working. But this would be your speedo and your tacho gauge, that would be in there, rather than having a speaker in there. But for this customer, he preferred to have it that way.

So we listened to them. They got it. All right make sure I got everything covered for that. All right, Zack, if you can zoom in on this. Everyone's lovely instrumental gauge.

Now again on this bike. And it was a hot mess going through this guy. But we had, let's see, we had all seven wires coming out of here. Obviously, you guys mostly know this. You've got your engine, light, you're left, right.

And then you're gonna have your high and low on here as well. And what we had done on this one, we had to wire this one to work off this gauge and data bus. If you're upgrading your system and you're putting in a new radio, deck, amp, whatever, it may be, a lot of times you're gonna have interference with this instrumental gauge up here in the front. Our deck and mounting bracket that we have in here, we had to modify it and also put a new one in. This was too wide.

This was the OEM made for the- I think it was a Road Glide or something. Or Street glide of a different year. But anyhow, we didn't have a large enough space to fit this in. So we had to modify and make a different one for the inside here. So when you're going through that, these are small things to keep in mind that can be a pain and you know way going through them.

So just make sure you're giving enough clearance for your components. But otherwise it's pretty straightforward, like replacing out your gauges. And when you're doing these, if you're not doing a connector on here or any component on your bike, make sure you solder with them pretty well. And when I mean pretty well, done well. Those soldering points could come down later in your riding days and prevent or actually cause some issues going down the road.

So make sure that those soldering joints are good. And then I also recommend a little piece of heat shrink over the top, if you're not putting a wire sleeve over it. I always tell the guys, you know, we take great pride in our work. Same thing when you guys take that thing off, you want someone to jaw to drop and see you did a good job. So keep that in mind.

And this was actually the original one that was on there, and then I see it. And you can see how large that was, and replaced to that. So that's what we did in the front end there. All right, instrumental gauges, headlamps set up and turn signals. Now here's the fun stuff.

Here's what everyone typically gets their hands dirty with. Changing out headlamps and the turn signals. Now given that you may have a softail with fog lights. And I mean the options are endless of the setups you guys may have. When we go through this, number one, make sure you unplug your battery and or pull that fuse out.

And going through this headlamp, we have 3 prong setup. Now on the back end of these headlamps. This is a HaloMaker headlamp. You can see right here. This is a halogen one.

So, a lot of times, you're gonna have to get an additional module to help with mediating the amps or the watts going to your headlamp. A lot of times you've got to refer to the manufacturer. I can go through the different setups and everything with you now. But double-check when you buy a headlamp. Because it's as simple as usually taking your existing headlamp, taking off the trim, taking off the housing, and then just inserting it.

Nine times out of 10, you're gonna have the same connector. However, sometimes like on this one, on the back end here when you open it up, this guys just pop right out for the most part. You gotta be careful of that. I always like to open it back up, double check, maybe shoot a little bit of dielectric grease in here, close it back up. Otherwise these headlamps are pretty straightforward.

Like I said, make sure you check those modules. If your headlamp is having issues, where it's going in and out and not working some of the time what you wanna check is going routing the wires back. And anything within your bike, that's where you start your source. And then you work your way back through the wire and then see where everything goes. But if you're having issues with that going in and out, typically it's this terminal on the backend of your headlamp.

One of these wires has pulled out or has come loose or it's been spliced. Some of the time, we'll see these wires where it's frayed down. That insulation is frayed down from the actual wire and it's either grounding out or possibly just giving us another issue. But check this, if you're going backwards, check that and make sure that's set up. Now turn signals.

All right, these were the pain. So we did these little nice little slick turn signals, coming right out of the trees there. And with these, we had, I think it was a total of four or five wires coming out of there, if I'm correct. Now, these are interchangeable as well. These are LED setups and this one was pretty much easy, pretty easy to mount, two straight bolts going into the trees.

Now with the wiring of this, this is what caused the issue. You can see the wires coming out right here, bringing it over. Connecting those wires and bringing it out to the handlebars when we're mounting or changing out turn signals. If your actual handle controls right here, don't have all the necessary wires coming out. Typically you're gonna have to pull them out and put them back through.

And what we've seen in the past a lot of times, and customers, you know, kind of shake their head at, is why they're getting, the activity of, the turn signal is working sometimes, other times they're not, it's within your handlebars. So if you're gonna route additional wires or change those up and you do need to add a wire. If you're in that kind of case. What I suggest for running these through, is make sure that hole, that you have to run your wires all the way through on both sides is debarred. You're not catching any metal, you can actually run your finger all the way through it and you're not gonna cut yourself.

Then you know you have a clean area to work with. Otherwise when you're pulling that wire through, which is just gonna go on that barrel, it's gonna start chafing and getting that insulation up and exposing that wire to a potential ground or a hot lead where it's gonna be a firework show for you. So you're gonna be putting on a show for your neighbors. So make sure those holes are debarred, they're brought down and then running this through. We've done this a few ways.

One is to actually drop a nut with a string through and you can blow it through with an air hose and run that down. Otherwise you can take a code hanger and run that down. And when running it, after that point, tie all your wires plus an extra couple on there and route them through. Cut your wires, giving yourself maybe an extra foot or two, that way in case you do reroute it or something, you're not having to go through the whole headache again of routing your wires, just to replace turn signals. Like I said, this is not typical, but if you're in that boat where you do need to add wires for it, this is the way to do it.

So give yourself that extra foot, roughly around there, run the wires all the way through and get those all hooked up according to the manufacturers recommendations. And nine times out of 10 at that point, you're gonna have a nice set of wires or loom coming out of there and everything should be up and functional. The other area too, that we've run into is, sometimes when you're pulling your hand controls off, or even the perch for your master cylinder, or your perch for your clutch lever, you can bind those wires pretty simply. You don't need to necessarily have to take the hand control covers off or housings off all the way. Loosening those bolts to adjust your handles, if you're putting, you know, you want a different degree or different set on there, where you're a little bit more comfortable.

All you really have to do, is catch a wire by the side and it's gonna help put that one, create a headache for you. So double check to make sure all those wires are tucked in and nicely down here. And they're out of the way of everything. And I like to do is once we get the bike up and running, working and perform what it needs to, plug everything in and check all your handlebars. Actually try moving these as well, to make sure you're not gonna run into any issues.

And that will help. So kind of leading back with the turn signals. Otherwise it's plug and play on these. We actually hardwired them all the way in. We didn't do a connector on there.

A lot of times we'll hard wire things that won't need to be serviced frequently. This guy's gonna keep these on for a long time. So we hard wire those in with a lot of other components. But if you're gonna actually have these, where they do come with connectors on there, make sure that's a solid connection with the female area that you're coming back to. Put a double dielectric grease in there to help out.

But just make sure you get that extra push in there and it's sealed up and working for you. Otherwise turn signals, they're pretty easy and pretty slick. The only area that I can think of off the bat that, you may run into is now they've got a whole setup where the mirrors are fully, not actually just came up with, but the mirrors have all the gauges put into them. We did a bike for a former vice president, Joe Biden, and did all the gauges inside the mirrors. And the hassle that we ran into with that, is not only was the gauge of the wires so small and hard to work with, but we had about 12 wires coming out of each one.

So the turn signals were built in there, along with all the speedos and tacho's and high lows and engine lights and yada yada, yada. But running those through, we had a great chance and I believe we actually did and one of the wires cut under debris. So if you're putting something up on the handlebars for your turn signals, just make sure you're taking extra precaution with those. Those wires are gonna be very slim and fragile and not the pull it against your source or component. Otherwise with turn signals, we don't get too many of the complaints with it.

And it was pretty straight forward from that point. Turn signals, headlamps, let me just checking in with the chat roll, see how you guys are doing. Cool. All right, so running the handlebar wires. Now the hydraulic ABS unit, this fun one.

Something non electrical with this, when you're flushing these. A lot of bikes nowadays are gonna have these guys, you know, built in there. When flushing out your break or rebleeding it, you're gonna do it normally like any other bike, and run through it. The actuator inside or valve will allow for everything to flow right through, allowing you to flush it and keep pressure against it. However, now when we get in the boat, where it's turned down and the actuators should be reading, or the electrical transmitter in there, it's gonna be putting off signals.

So every time you're pulling in, it's activating and allowing different kind of pressure to go through. When this is not functioning correctly, sometimes it's hard to tell. Other times you can tell right off the bat and say, okay my front brakes about the go on me, or it's seizing up, whatever your case may be. This is where you gotta come back to, this guy. So pull off your outer fairing, like we did, locate your unit and kind of go through it.

Sometimes I've seen it, guys have done aftermarket modifications on their bike, and what they did on this, is they routed on their own circuit. So if you're running on its own circuit to avoid, you know, the gauges working off these together, then you gotta look at that one fuse in the back end, if you didn't run it that way. Otherwise if you ran a directly back to your accessory point or run point, on your ignition switch, you gotta look at your connection down here. So you're kind of eliminating the fuse and coming back to the connection. That's what we wanna look at.

So even by me, if you can zoom in on this Zach and take a peek at this. This is one we actually hardwired in. Again, like I said, but just by me pulling these wires just like that will cause a malfunction to this unit. And that's why when we're pushing these in, make sure everything's clicking in, these wires are pushed all the way in. Pulling these out just a little bit will start to make the thing go havoc and haywire.

So number one, check that connection right here. And if this is connected, say you do have this worst case scenario, let's put in the play that it's on the fuse or relay, that's fine. Connection's fine, it's not binding, it's not running into any issues. Then it's at your actual unit. You wanna then pull this out and kinda test that one as well.

If it's not, the other area that I can tell you to take a peek at, is pull the connection off, turn the bike on, what I've got is, we either do a multimeter or a test light. Test light it's easier, so if you're just going after hot leads or trying to find the grounds, which you'd just reversed them on the terminals. Or just use a multimeter and figure out where, which wires, which these come into play. I mean, you're gonna use these all the time I guess on your electrical stuff. Reading ohms resistance and giving you your voltage amount in an amps.

So I would take, first thing first, take a test lamp and go to each wire on the inside, or if you can poke through on the outside. I don't necessarily recommend, I see a lot of guys that would just come back here and push right through the installation. Now, once you do that on any of the wires or trying to test and diagnose an issue. Once you put that puncture into that wire, now it has the ability to open up if you don't put heat shrink or some kind of mesh over the top of it to cover it. So try avoiding that at all costs, if you come down to it where you just gotta poke it through.

It's not the end of the world and you're not likely to have an issue but that's another one you'll run into. So check the connections on there, make sure those are all set and you should be good to go on trying to help get that together. So I won't mention just kind of covering everything, in a recap with electrical. When diagnosing this as a few steps that we can always take and what we do taking these steps. It's kinda going through a checklist.

I would recommend putting a handwritten, list together saying, check the battery, check fuses on and on, and that way you can go down. So what I would put in that list is, I would check the number one, to make sure your battery is charged. Sometimes we're gonna have some of the sources working. If you don't have your bike up and running. And for some reason you turn it on and you're only seeing a few things work.

There's a lot of components that demand a certain amount of volts to operate. And there's a minimum requirement for that, so check on that. Secondly, go back to your fuse block. Or if you have a main fuse or two accessory fuses, check those right off the bat. What we have on this one is we have one main 40 amp fuse and then we've got two on the back end right here.

We've got a 15 and a 10. Those are working off two different circuits up here. So check the fuses, go back that way. If you have relays back there, check that those relays are clicking and those are functioning. If everything is in order with the back end, right on the seat, I would take a peek at all your connections.

Now, a lot of times I see guys, putting their own connectors on. This is something to take your time with, because once you get into, I'll actually show you. Get into these pins, it is very easy for these guys to pop in and out. Now there's different size pins. So make sure if you're doing your own connectors and if you're doing SAE connectors, make sure those are the right size for these.

So what we've got here is a Two Prong. And this is gonna be, can you see that. That's the inside and this is where the connectors are gonna go directly in there. From the outside we've got the female pins. This is what a lot of times, this is the setup.

It's just different looking connectors you'll have. These are the female pins. Now when we insert one of these, I'm just gonna take them off here. You're gonna hear a click. I'm not sure if you can here it with me.

But a lot of times you're gonna hear that thing click. That's not gonna click for us. Make sure it clicks all the way through. Make sure it's all the way in there, because you have a little tab right in the back right here. That's what's supposed to go in there and secure it from coming back out.

And you also get right on these two little tabs. We have one tab, this top tab, that's actually be crimped on the wire. Make sure that one's crimped fully on the wire. The second one is gonna be crimped right on the installation. So remember that if they're both going on the wire, I mean it's not necessary, a lot of times that's where I learned it from in school.

You got have that separation. So making sure that these are crimped on correctly, and also that it's not gonna come loose out of there. So give yourself a good quarter inch of wire to come through and before crimping everything, don't have it too long, because once you try and insert that male pin into here, it's gonna hit those wires and not allow for it to securely come together. So if you're doing your own connectors on your bike, make sure number one, that you crimping it correctly, connect to those all the way in. And if you're not getting into secure placement with both of these, it's likely that number one, the pins being pushed out.

Or number two, that male pin can't push in. So with that, in terms of kind of troubleshooting and looking through our bike, making sure those connectors are all the way pushed in. For instance, if we're working, what we did on this one is to just female terminals gonna the back end. But with the main gauge. You know, we've got a seal right here to help with waterproof.

And then we've got the two tabs on the side. You really gonna make sure that's pushed in there. And it's in the correct position. A lot of times you'll see, that there's an indentation on the corner of the connectors, which will only allow you to put in one certain way or otherwise you have a step up on there or some kind of we call them tangs, that'll push it in there and make sure it goes in the correct way. So make sure those connectors all the way pushed in.

And that's another source that you wanna look into. Once, those clicks are always a good noise. Not the clicks where you're breaking off tabs, but the clicks where it's going in correctly. So on that list, next thing would be the connectors. After that, kinda route your wires back.

And figure out if you're hitting or doesn't obstruction of your wires. So if we're running this wire all the way back, and we got these things moved around. Running these wires back, make sure it's not pinching or binding against another wire. Or if for some reason you overlooked the mounting point on for say this, and you got a wire caught onto here, it's grounding out or otherwise it's a hot lead. That's just not gonna allow for that function to work.

It's amazing how wires get into certain places on your bike too. They will work their way around. They're like worms sometimes. Make sure they're securely fastened. So make sure that wire or wires aren't being obstructed or getting binded or pinched.

And then if you've gone through all that, and gone through kind of the manufacturer's recommendations of troubleshooting and what to look for, my next recommendation would to be looking at the actual source or what you're using there. And seeing if that's faulty or if that's something that's under a recall to a lot of times with manufacturers or Harley, you'll see those recalls in there for good reason. That's the reason eventually those things happen. So don't forget about that area. And we could go on and on and on about electrical stuff.

But for the most part, those are the areas that you should cover. Now before I keep going, we've got a couple of questions that did come in that I wanna touch on regarding key fobs. One of them changing the headlight, headlamp and then, issues with the speakers not working. So first off with program or programming key fab. A lot of times you don't need to take them into the Harley dealership.

So there's specifications and just by searching out there and, you know even Fix My Hog, there's videos on this. But a lot of times all you're gonna do is a certain amount of turn signals and or placement of the ignition switches to get it down. So for instance, on let's, I believe, I don't see the year off him, but normally the security code is gonna be five, sevens in a row. So seven, seven, seven, seven, seven. And what we wanna do, is initially set the bike to the run position.

And turn the ignition over the accessories. And then on the left side, we're gonna hold the left turn signal and pop it seven times. Use the right turn signal as your enter button. Now we're gonna do that. Let's see if you've got seven, seven, seven.

We're gonna do that five times at the number of seven. So we're gonna hold this side, and then we're gonna hit this seven times to get us on number seven. And then we're gonna hit our right signal to get us an enter and brings us back. So we're gonna do that five times to get that, bring it back, hit both turn signals, and then hit your switch off. Typically the turn signals will flash.

And once those flash, that gives you the clearance or the okay, thumbs up that you did it right. And then check it again. A lot of times, if you're actually working off security too on this, like for this bike, we do have a security sensor right here, the fab sensor. And I wanna make sure that things not going off and make sure you do put this in the run position and work off that and pull that fuse. So that's my recommendation.

Check out some of the other videos that we have at Fix My Hog for that. Otherwise you've got that ability to do it at your at home and just go through it like I said. It's just sometimes a couple of buttons, all depends on what year model bike you have and looking into what kind of fab. If you're upgrading certain things, manufacturers will have recommendations on how to do that. But no, you don't have to go into a Harley dealership to get that taken care of.

Additionally, we had another question for speakers not working. Now, I saw that you took it in for throttle sensor and that came out working but your speaker doesn't work after the radio deck being on and all your electrical stuff going on. And I think your point was that you want to, if it was just a loose wire, I can almost guarantee it. It was a wire that probably got pulled on unintentionally out of there. So by removing that outer fairing, going in and just making sure you have secure terminals up to, button up here, would be my first recommendation.

I can, like I said, I almost guarantee that it is a loose wire there. Otherwise if you have both speakers aren't working, I just saw that one speaker wasn't working. Both speakers aren't working, run it back to check on a fuse or to make sure everything's plugged in on that. So otherwise a lot of times when you're working on these bikes and you're going through, you've got your crimpers in here or whatever tool you may have. Sometimes you just pull a little bit on a wire and it pulls out and that could just ultimately lead into the headaches that you're gonna get.

So that's something also to be careful of, when you're working in there. Make sure you have enough clearance. And a lot of these components are certainly delicate little things. So make sure you're gentle in moving around with that. All right and then we have, changing helmet for an O six classic and looking for the fog lights too.

As I touched on a little bit earlier, it's mostly plug and play with these. Now with some LEDs or halogens, they're gonna require a modular resistor to help with the flow of electricity to that, to make sure you're not overloading. There's tons of vendors and manufacturers out there, that just recommend just doing plug and play. So if you're getting one that you can just plug and play, it's as simple as just taking off your outer fairing and taking off that headlight trim, right on the outside, pulling your headlamp out and then pulling that connection off. Now, remember when you're doing anything with electrical, we're gonna disconnect that battery.

We're gonna pull that fuse directly out and make sure everything's disconnected. Because if you don't, there's the problem of running into more things. There's another question here. What do we got? It's from Danny.

His 99 Dyna is getting fire. He replaced the coil, relay and ignition, could it be the positioning timer sensor? Yes, absolutely. Absolutely it would. If you went through, nine times out of 10, it's usually the ignition coil.

If you already have that pinpointed out, I would definitely look at that sensor. Which brings up another point, with these sensors, they're extremely sensitive to potentially heat too. So what we have, a lot of times you'll hear people saying heat sync. What that is, the fins built onto like an amp that provides the coolant or the airflow to help cool that specific source down. But with these sensors, a lot of times, you know when we have them built in, we've got sensors up here on this side and then we'll have some down by the manifold.

Just by those being off a tad are not reading will put your entire electrical system out of a commission. And nowadays, a lot of you guys have seen, we're not going backwards with less wiring. We're just going forwards with more wiring, more sensors, more it's just gauges. And it's so digitized, now that we need computers to read the computers and map them and program them. This that, and the other.

So I would suggest Danny to take a peak at that, if you ran through the ignition coil already. And that should be definitely your source. So when I was going on with them, O six classic, like I said, just remove the headlamp, the trim, re-install. Make sure that mounting position for the headlamp matches up on there. A lot of times they will.

But in the instance that it doesn't, like we had on this front one, we have to custom make the mount for inside. I believe this was a hog word swamp, but this trim was a lot larger, and we wanted this one to come out rather than being flushed on the inside. So we had to go around and do a different mount and also rake that out and adjust the suspension. So we had the correct pitch on there as well. So a lot of the stuff is easy but, the hard part is figuring out when it goes wrong.

Installing the stuff is easy but coming backwards is the hard part. So as I mentioned, that list is super, super handy. We've got kind of a check mark list that we run down for a lot of this stuff. And nowadays they just have programs just like cars. We can plug in and it's gonna give you a code, on the newer bikes and narrow down those possible areas for you where it can go wrong.

But if you've got a lot of patience, this is the job for you. Logical, if you don't have the patience, it can be a headache. One of the last things I'm gonna mention with electrical stuff and specifically, I've been doing this for over 15 years. I'm more on the fabrication side and get that stuff, love that stuff. But when we get down to the electrical, I'm so detail oriented to the point where, it's bad.

I guess the guys get ticked with me, 'cause it takes about 10 times longer to make sure everything works. But when doing looms, you know, there's black sheeting. You can use, you know, these plastic stuff. It works pretty well, it helps protect the wires. But when you're going down and doing it a more, I guess, a challenging project, like if you're doing a whole setup like something like this, make sure you're running additional wires.

Make sure you're protecting those wires. Make sure those connectors are always put in. Like I said, on this one, it was weeks and weeks of rewiring and getting the computer to read differently. And it's a big deal when you pull off, for us we pull off someone else's work with the outer fairing. I know what we're working with just by looking at the work that was done.

You know, the craftsmanship, the handmanship inside there. So when you're doing that, not only does it look good but it sure does tell a lot that you did take your time and you're probably not gonna run into binding issues, things fraying off. And then ultimately you're gonna have a long time term bike without any electrical issues. So I guess that we can go days and days on electrical stuff, but for the most part, touching on upgrading your gauges. You know, to the recap, you're just gonna pop those things out.

Make sure the plugs are already secure in there. Nine times out of 10, those six gauges you're gonna be using are just plug and play with the dimmers in the back. And then if you're adding a whole new speaker system, which is definitely able to do it at home. I think we're gonna be doing some videos on that. So you're gonna have to check that out, but you're gonna wanna make sure those are secured.

Number one and foremost, make sure those terminals and there's even a level of, how far you wanna keep all the electrical stuff away from each other, to make sure the frequency or transmitting doesn't interfere with one another. So that's a whole nother level electronics. But that's something you can definitely do at home. And then, you know, if you're working with your deck, your electrical stuff, you'd just got, for your tunnel, one power coming out, making sure that antenna is in a good site, for picking up a signal, to give your AM or FM signal out there. Or if you're doing a like a serious, this is a serious one, just plug and play.

And then last thing I'm gonna mention is, with all this, take your time, go through it. I know it's a headache, believe me I've been there. People get angry on how mad I get with some of this stuff. But at the end of the day, take a look at the likelihood. And the the first thing that something could be in, it's typically a fuse.

Don't overlook the easiest part of this. So that's what we got today in today's live event. I appreciate all you guys tuning in and the questions. I hope I was able to help bring some less headaches to your head and go through this. Make sure you tune in next month for our next live event and got any more questions, fixmyhog.com and put in your questions there, and we'll get on the overtone.

So, thanks guys, have a great Tuesday and happy Halloween to everyone.

Share tips, start a discussion or ask other students a question. If you have a question for an expert, please click here.

Already a member? Sign in

No Responses to “FMH LIVE: Gauges – Info and Troubleshooting”