FMH LIVE: Top 10 Things to Check on Your Harley

Tommy CrealTommy ‘Clutch’ Creal was LIVE on Wednesday, February 27th at 1:00 PM CT where he reviewed the top 10 things to check on your Harley. After watching the video click on each one of these to see more FMH videos on the topic. Make sure to share your Hog with us on Instagram #ShareFMH

Spokes / Tires

Fasteners

Air Intake Bolts

License Plate Bolts

Battery Terminals / Cables

Handlebar Housings and Bushings

Levers / Running Boards / Pegs

Motor Mounts

Hey guys, welcome to this month's Fix My Hog event. I'm Tommy Creal, contributing editor to Fix My Hog. And today we're gonna be rolling through this CVO Softtail Harley we have here and going through some of the components that you should check on pre-rides. And then also I'm gonna dive into broadly some of the components that you should be checking throughout your time on the bike. So whether you're going for a long ride you're going up to Sturgis down to Florida, wherever you may be going, those components we're gonna take a look at and give you kind of a shortcut of what to look for.

Before we jump into things, make sure below that chat box, you hit that free download for the troubleshooting with a Harley codes there. That's free video great little tips and tricks in there. So make sure you download that and check it out. And then throughout this time for the newcomers, I got my chat box rolling over there for you guys, so if you've got any question or you wanna see a demonstration or something, we'll make it totally interactive with you guys and drop your question in there or if you want me to cover something again we'll kind of roll with it there. So make sure you get involved in that chat box.

I'm gonna be checking it frequently over here and we'll get rolling from there. So additionally make sure throughout your time riding and no matter if you got a new bike or a previously used bike, you're sharing it with us. #ShareFMH, so #ShareFMH on Instagram. Make sure you're sharing it with us. We'll get it out there as best we can and get you some exposure on it.

So thanks again for joining us. And we're gonna dive right into this. Hopefully Zach's on his Zoom game today 'cause we're gonna be going into a lot of the fasteners, some of the bezels we're gonna go into our interfering here. I'm starting to look like, look at what could get loose in that predicament there. But chose this bike because there's a lot of aftermarket components on here nowadays.

Obviously with our street glides and road glides, twin cams in general, we're doing a lot of making up. So buying that stock and throw a lot of chrome on or a flat black and go in those directions. So when doing that, you got to take some time and make sure those new fasteners, those new nuts and those new seals are seated correctly over some time with the bike. So that's why we kind of got this bike up here on the lift to show you guys and obviously still referencing some good stock components on your bike as well. So not too much to change in there.

So top 10 things I would suggest to look at for pre-rides. And if you need me to slow down, drop it in there but I'll cover it again at the end. Top 10, I'm suggesting you guys take a look at all your fluids. So take a look at your oil, take a look at your brake reservoir, how much brake fluid you have in there. Go all the way down and just go front to back on all your fluids.

Additionally, obviously our tires, our rims. If you're running spokes, you're gonna wanna take a look and make sure those spokes are tightened up, they're not loose and they're not bent. And also the tire pressure obviously is gonna be a big deal with weather changing and all that. And for you guys on the West coast or East coast, in the Midwest, we're going through a little cold drought right now so your air pressure is gonna be fluctuating. So make sure you check that as well and not over tightening spokes.

Additionally fasteners, now this could be a much more lengthy endeavor than going right through and checking your tread depth right on your, you know, your tires or your pressure. I would highly suggest after, you know, 500 miles, 2,500 miles, 5,000 miles, 10,000, you kind of clean sweep your bike and checking off fasteners make sure they're still seated, they're still holding in the position you want them to. And even on your pre-ride and that's... You can kind of take a look and use the chat box, not the phone line. So kind of run through that and make sure those are all properly seated.

Air intake bolts has been a big one. You'll see numerous times, there's probably some funny videos out there but time and time again, those nuts or those bolts will back out on your intake. And if you have an aftermarket one, this is a really big deal to double-check those. Excuse me. So kind of take a look at the air intake bolts, make sure they're seated correctly.

If you have counter some bolts, make sure those are all the way seated correctly in that outer portion and you won't know till that sucker is going down the road if it was on tight. So double check that and it's easy to do. It's quick, I know you're Jonesing to get on the road, get rocking and rolling, but take a minute and kind of go through these. Number five would be the license plate bolts. Now that seems to be just stupid or kind of out of the blue, but those are a big deal.

Obviously you don't wanna lose that sucker down a trip. But it's very easy to make sure those four bolts are seated. If you have reflectors or lights on there or any of those aftermarket components double check that those are seated all the way in as well. And you're ensuring that you're not gonna be losing the license plate on shorter long run that you have there. Additionally, and I'm gonna slow down here in a few minutes and give myself a break from talking, but battery terminal.

Make sure those bolts are nice and snug up on here. If they're a little bit loose, you're gonna call some arcing. And what's gonna happen with that throughout a small period of time is actually you're gonna lose power and draw those amps and at a severely high rate rather than having that battery recharge. So you're actually draining your battery if those are pulled off a little bit. This is something simple to do, I'd highly suggest using a socket rather than using the Phillips.

It's tempting to just put your Phillips right in there and crank on it but you're gonna strip that material out pretty quickly. These aren't a chromaly or hardened steel type of bolts. So take a look at this and even the terminals around the battery as well. This one, we had redone the entire front end with new gauges stereo system and all the bells and whistles and had to hook up a couple additional wires for those batteries and gauges. So we obviously having a spike in, double checking all these to make sure they're properly seated not interfering with the seat as well.

And the fuses, those are gonna be either on your left or right side and on road glides or street glides, make sure those are all the way seated as well. So I'll go a little bit more in depth on this later on, but for pre ride that's what you're gonna wanna take a look at just making sure everything's secure on there. And then moving on, handlebar bushings and switch housing, those two are the other major areas to look at. Now, obviously it would totally suck to be Jonesing down the road and all of a sudden your switch housing starts moving up and down, which has happened time to time with bikes we've had in. And these two little bolts, one on the top, one on the bottom here, they have the tendency to back out time to time.

These are typically button heads or Allens on different manufacturers. But take a look at these. And what can happen after not only just having this loosened up is that those wires, if they're internally run or externally run they're both gonna be starting to shear off and split and splice a little bit. And obviously for the sake of keeping your brain intact and not losing your stuff, your marbles, we wanna make sure those don't have any interference with the bike. So it'd be a costly and longterm fix and easily avoidable at the same time too.

So make sure these switch housings are nice and tight and that you're also not binding up on those wires. That can be easily done. I've done it time and time and caught myself because you're not slipping them directly under that dimple that allows you to get it through without splicing it. So take another look. As you've seen in many of our videos here on Fix My Hog, we preach about working safe and clean working environment but also a double and triple checking your work as well.

So this would be something to double and triple check. And then handlebar bushings. This can be... Well, I don't have the right word for you, but this, we can overlook this one pretty easily. Handlebar bushings are gonna be obviously going through our top triple tree right there.

And those are made out of polyurethane. And what those actually do is help us prevent a more rigid ride on our handlebars. So if you're running eight hangers or drag bars, those are gonna prevent a little bit of a play or those are gonna allow us a little bit of play for a smoother ride. So you're not jamming down the road with your shoulders locked up and continuing to just put your back into stress and need to attend to that later on. So double check those, make sure they're not cracking.

Just pull the chrome covers off of them and make sure the bolts seated as well, going up to the handlebars and you'll be good to go on there. So that would be another item. If you have the accessibility to look at before your pre-ride, take a look at those handlebar bushings as well. If you're down there and looking at that area, I would suggest looking at that top riser clamp or a triple tree clamp you have right there holding your bars down. Those time and time again you can see loosen up on this bike specifically and other baggers as well.

The amount of stress you're putting on those bars whether you're pushing it up a hill, pushing it, you know just directly down a road that's flat, you're still applying pressure in trying to move those bars. So that top riser can lose some of that strength up there in those four bolts or whatever pattern you may have can actually start backing out a little bit. So that would probably be the last thing you want is to be down the road again and have that happen. So if you're there, double check it and if you pull those out, make sure you're applying a threadlocker as well which I'll get to the different thread lockers and purposes later on, but you're gonna wanna redo that. And then the two other things for that top 10 countdown for us here would be some of the cosmetic components or bigger components like our levers, our running boards.

As you can see down here, we have these slick little running boards and the lever. Make sure those are all buttoned up and tightened up, those bottom bolts right there had those Nylocs on them, those come back out pretty easily. So again, you wouldn't wanna lose a 500, $600 piece of chrome down the road just because you didn't check it. And then lastly would be the motor mounts. Depending on the year of model that you have, double-check and make sure those are all tightened up, take, you know, just a wrench, try putting some pressure on it and getting that thing, making sure those bolts are all tightened up and you should be good to go.

So refreshing, give myself a little break here. Top 10 lists that we're gonna check out the fluids, make sure we've got at least semi fresh fluids in there that are all topped out and still looking fine and not contaminated. We're gonna go through and we're gonna check out the tires the rims, make sure the tire pressure is on point. And from there we're gonna move on to our air intake bolts. And yes, it sounds stupid, but like I said, stupid simple.

Some of this stuff, we just wanna double check. So air intake bolts, license plate bolts while we're at it too. And then we're gonna move into the battery section right here and seek mounting bolts as well. Switch housings, switches, handlebar bushings top risers and floorboards. So Holy cow, that's a lot of information for you right there.

Hopefully you got some of that. Again, if you've got questions on that "top 10" pre ride checklists there, please let me know. And obviously depending on your bike and what you have, that can vary on some of the things. But what we're trying to get across here is that with the pre ride, you don't wanna take two hours and go through your entire bike and make sure, okay, you know, this chrome cover for my ignition coil is tight, that bolt on the back is tight, you're going through everything. Make sure the bigger components are buttoned up and nothing might have happened to those.

You'd be amazed at what potholes can do to your bike. Not only damage it, but it could pop a fastener out pretty quick. It can loosen or bend stuff. So that road can really, even though you're gripping and ripping it, can take control of your bike and some of that. So just take your time and look at the bigger components front to back.

And at that point, once you get that stuff done you're feeling comfortable with it, jump on your hog and rip it and have a safe ride. So again, any questions on that, I'm gonna check the chat box here to see if you guys are tossing anything just yet. And then I'm gonna start... All right, thanks Dennis. I'm gonna start from the front and, again, if you have any questions, put it in there but I'm gonna broadly kind of go through some of this and what we're looking at and what to look for.

All right, my camera man. How're you feeling? Can we see this over here? That'd be good. All right.

So starting with our big wheel up here. So some of the things, if we have this thing in, after, you know, 25, 5,000 miles, we're gonna take this kind of approach and look through things. So if you've got miles on your bike, I would take this into consideration too. Clean sweep it like we're gonna be doing here. What we had done on this bike, 'cause we had put the fork boots whole front end like I said, this was a CVO.

So this whole entire street glide front end was replicated on here with a new neck. So these fork boots and or these fork boots in the legs, we're gonna check inside here on our fender mounts. A lot of you guys I've seen toss new fenders on wrap arounds and snugging those up to the big wheels or even stock wheels. And inside here, this is can be at a critical point because the aluminum billet that you're using on your fork legs here can actually, I'm sure by experience with some of you guys, can actually shear out and cross thread pretty quickly and obviously losing a lot of tension and strength in there. So we're gonna double check, make sure these are tightened up with a half inch wrench right here.

These are going directly into our leg. And for the detail oriented mechanics and fixer uppers like you guys, what we've done in a lot of our painted components is that we're always put a flat washer against the painted part of that area. So this fender bracket that was fabricated we put that chrome washer there. And the reason being is that when we're applying pressure and same thing, when we're riding, we're not gonna see that paint peeling off, it's kind of a semi half-ass preventative of that happening. So that's why you see these things here.

And when I typically do is I'll run my finger and see if I could spin a washer or two. And if I can't, that'll be snug but we'll double check the backs here. Again on here, we're double-checking the actual fender to the amount and making sure those are secure as well. Now, which you can't see on that side but we'll get to it on the back as a caliber. We've got two mounting bolts on the front end gonna our fork leg down here.

I don't know how skilled you are back there, buddy but if you can see a finger or two right here. What we're gonna be checking is actually that those are still snug up from this side. And from a quick glance on our rotor right here we're gonna make sure that the caliber is still centered out in those brake pads, look to be at least even for the most part, and they're not wearing differently. Also a little tidbit of information is that you can tell some of the wear patterns on your brake pads by looking at both sides of your rotor. Obviously not right after your ride, it's gonna be hot, but let it cool down and you can see different wear patterns on the side.

So brake caliber, check that out, make sure those two bolts are tightened in there. Take a peek at the pads, make sure they're both on the normal side of wear and tear. And also get into that fitting right here and make sure that's tightened up and same thing with your bleeder. If you have put a new, you know, whole new lever on and reservoir for your master cylinder up there, you obviously had to re-bleed your brakes and go through that component. So double-check those, not as likely, but have the tendency to time and time to back out.

So you might be that one exception for not checking it that one time. Additionally, we've got a custom Curio and headlight trim right here. So we're gonna double check and make sure the bottom clamp is snug up. Always just pushing against the headlight, make sure that's still seated. With this bike, what we would actually do is pull that trim off and make sure that seal behind there is still properly seated just because of, you know, obviously you're gonna catch yourself in the rain one of these days.

So making sure that seal is still properly seated in there as well. So make sure you check that headlight, no matter if it's mounted like this or externally mounted off the bottom of your triple tree, double check that. And also the wires too, if they're not hidden, make sure those are still routed correctly and you're not gonna be binding against those. We're gonna be looking right here, this is our turn signal, smooth turn signal right here, but also behind here, I'm real glad street glides are gonna have a similar setup. Your interfering mount is going right through here along with your inter fairing.

So making sure whatever two types of bolts you have here, whether they be hacks, counter sunk or button heads, those of securely pressed in. And if you have to, for any reason, take some of these bolts out and you see a blue marking on it, obviously many of you know that's a thread locker, blue thread locker and blue is our go-to color on anything. So if you're pulling that bolt out, you see it, it'll never hurt to put a dab of blue at the bottom of those threads when you put it back in. Just making sure we're being consistent all the way through. Additionally, what we're gonna look at on the outer fairing is our seal right here.

How are we looking, camera man, can you see this one? So our bottom seal right here is actually a little bit loose and these are hot glued in on our end. So we're gonna go through, pull the outer fairing off 'cause we wanted to get in there and check everything internally. But what we're gonna be doing is getting the seal properly seated again and remounting this outer fairing. So road glides and street glides fellows and ladies, make sure you're double checking your seals.

I can't stress enough how important those are, no matter if you're on a fairing, an intake or whatever it may be, that those seals are correctly installed and instill seated properly. So some of this may seem redundant but I wanna make sure you guys have the right information and right direction to go to here. So bear with me on that. Some of these cosmetic components, believe it or not, have the tendency to back out as well. So we have a headlight trim right here that just went on the other side of our mounting bolts for our fairing, including our windshield.

We're gonna double check, make sure those guys are in, this windshield is still nice and snug up there and still seated correctly all the way down. Time and time I'll see those kind of pop out a little bit which will lead me towards thinking that these bolts have backed out a little bit and we will obviously pull those out, apply blue thread locker to it and then put those right back in. So kind of looking on the outer shell, that's what we're gonna be running through. If you've got questions on that, drop it in there, that chat box, but to kind of recover make sure we're checking our fender mounting bolts, fork boots, you know, those are kind of tough because you gotta come in from the other side of those two bolts. But just make sure you've got nothing leaking, your seals aren't leaking.

Go through here and make sure our axle spacers are still intact. Brake caliber, that's still aligned. Brake pads are still looking good. Our rotor is still wearing properly. And then make your way to the headlight.

Turn signals will be somewhere on this area, up or down and your fairing, so. That's the start of it. Now what we have on this side, man, I really wish I could swing this. How are you doing on that? You think you're doing...

Use it. All right, cool. Teddy bear, All right, so what we've got, I'm gonna actually jump on this side so they can see. They can see. Can you see this stuff?

Can you see the internal instrumentals? Little bit. All right. So I'll do my best here guys, but... So when we're looking at kind of the council of our bike right here, we've got obviously our radio, our deck, touch pad, whatever model, make will vary.

Instrumental gauges, in this instance, we have our speaker right here and then also on the outside with our tutors installed as well. And then our cover up down here under the fairing. Now, considering that this was something that was done aftermarket and even with some of the stock applications here's my suggestion though to look at. Removing that outer fairing as I mentioned earlier, what we're gonna look at from the inside, is that those brackets and seals are still properly seated on this inner fairing. Now, when we're putting these gauges into the inner fairing, we're putting the seal on and then dropping the gauge directly through.

So it's gonna be sitting on that outer bezel which will likely gonna be chrome, but making sure that's still tightened up with those nuts in the back. And also anything that you may have mounted up here. So the radio, makes sure that bracket still mounted properly. For us, one of the amps is mounted inside there so we're gonna double check, make sure that bracket is on as well. And then just double check to make sure there's no play.

If there's a little bit of play in here, something probably came loose, but these are supposed to be pretty snug up. And additionally, making sure those speakers are in the same situation, that those are snug. The outside and the bracket for those as well in the inner fairing are all snugged up as well. Now, getting to the handlebars and then we're gonna get everyone's favorite part of the bike, the wiring and the electrical side. Handle bars, what we wanna look at is, I mentioned earlier, those bushings, make sure those are number one, still intact.

That'd be a good thing if we still had those around. Also that those bolts going up to our risers or our connection point for our handlebars are still tightened up and there's no play in there. And then also making sure our top clamp is properly seated. So typically nine times out of 10, you're gonna see four bolts holding that down with a blue thread locker. Make sure those are properly seated.

If you feel like you need to make an adjustment, do it then and you'll be good to go. So double check those areas on your handlebars. And if you've run your electrical... Actually I'll get to that in a minute. But double-check those areas.

Also our grips, those are internally connected right here on our housings. Make sure those are all the way seated. We still have play. The fly by wires, obviously we wanna make sure those are still engaged. That's a pretty easy thing to make sure of.

Make sure it's still snapping and we're still getting some response to our throttle body or an induction down here. And like I said, the grips, just make sure those are properly seated. Now, we're moving to the clutch lever or the master cylinder lever and mirrors and reservoirs up here. I always like to double-check these pins. Now, the pins dropping the lever through, you see that.

C or E clamp depending on what coast you're coming from 'cause I think everyone calls it different from the different coasts. But making sure that's still correctly seated in that that beveled out area on there. I've seen those fly off time and time again after someone put one on and all it takes is for that pin to start backing out a little bit and all of a sudden it's all the way out. Your clutch lever's down the road and you're running into a stop traffic. And that's not where we wanna be going.

So double-check that. And also our clamps right here on our lever, the two torques right here, make sure those are completely snugged down and flush with the handlebar and the top of our reservoirs. Now, we've had our share struggled more recently with reservoirs leaking and we were actually dealing with an aftermarket company. You remember this? Big time?

And it came out to be a machine in there and about three or four of them, we had to continue to go back. So what we saw is that after a built-up pressure in the reservoir, we would get a small amount of leakage over time, that'd pop out in that time was frequently, we'd get it every five, 10 minutes. So double-check to make sure you have nothing leaking, leave it overnight, you know, pump it a little bit and make sure that's seated correctly after, you know, putting fluid in it. So that's a big thing. That's a headache.

Yeah, I get it. And a lot of times it's either the seal is just not working with you that day or you're fighting with your bike that day, so just take the time and try to take a deep breath and make sure that's properly seated and good to go. Mirrors are kind of self explanatory. There's not too much to 'em unless you have them coming off the end of your bars. You have an external clamp coming off, many other variations.

But typically you're gonna see 'em coming right directly in here on our perch right here. And it's gonna be one acorn nut on the bottom, flat washer and then either a split washer or some other locking washer to hold that there. So double-check that, that'd be a big bummer. Definitely if you invested in some sweet mirrors for your bike to make sure those are secure down and good to go. And if you're changing out any fasteners, I know guys, some of my buddies have ride that will change out faster and make it look a little bit slicker.

So for instance, you know, there'll be putting chrome, chrome Allen bolts in here and then flip putting a little copper button in there to make it look flush, or put an acorn nuts on things to make sure those are seated as well. So if you're kind of changing out fasteners more frequently make sure those are done as well. Man, it's a lot of talking. And the housings and the switches, actually, I wanna cover that a little bit more. With the switches in the housings, a good idea to deal with this is to actually turn your bike on and to go through...

We're gonna go through and just make sure everything's working. And then high, low, left, right. Bad reception. And just making sure those buttons are freely working in there, they're not binding or kinking inside the housings. Sometimes when pulling those off, the buttons will just dislodge a little bit and catch an edge or get a bulk of the wiring behind it to push it out.

So it's simple fixes nine out of 10 times. So double check and make sure those housings are working properly. It can come down to, I've seen one time when I was in Sturgis where my barber at the time, we had a little switch housing up there on the right side and my kill switch got jammed up there and completely killed my bike out, directly run it over to the rally. So make sure those things are free and moving over there. And then also I mentioned a little bit earlier those wires coming through.

Now, when we're taking off our housings and for say that you're putting on some slick aftermarket ones and we pull those out and we let it drop, what actually happens is we're pulling that wire out a little bit. So I know we get jazzed up and stoked to put it back on real quick, but at the same time, we gotta make sure and be cognizant that we need to put that wire back in there and make sure it's not binding or kinking. I can't tell you enough, and I know probably wiring and electrical is probably your favorite part of the bike altogether but... I can see you shaking your head. How much of a headache that can cause, a little six inch piece of, you know 16 gauge wire will completely destroy a room.

So imagine all the wires that we have going through here and the yards. And once those wires are all the way you know, together if you're aluminum together, that will take an entire circuit or system all the way out. So be careful of that. And even our data bus wires that are running through our handlebars on all our bikes now, twin cam wise, those things burn up and you're running back here to your ECM and ECU unit to reprogram stuff. Nonetheless redo all the wiring.

So be super, super cautious about that area and same thing coming out of the bottom of the bars. What I was gonna touch on this earlier is that when we're routing those internal wires, now to when we do bikes with internal brake lines, there's a lot of wires going through them. We wanna make sure those don't bind or kink. So when you drop those out the bottom of the bars and you're down there checking your handlebar bushings and your top clamp, make sure those are pushed off correctly and routed correctly. What I mean by that is that when we're our turning radius of our front we have either internal or external stops to make sure our front end doesn't completely turn 90 degrees and make us buckle like we're riding those rodeo things.

So those stops actually stop it sooner to allow a better turning radius and safety issues. But also it'll allow us to sneak some wires. And now this one, we actually just put the tank back on, so it's not as clean as I'd like it, but these wires, we dropped out of here and same thing here. And they actually go back up in here like this. So when we're turning our front end right here we're not gonna actually bind or kink these.

So if it's sitting on the stand on the other side and that wheels all the way dropped to the left that it's not going in and starting to rub against those wires. So it doesn't take much for a little smashing of a wire here or there to start a chain reaction with all that stuff. So take a peek at that, and I just can't stress enough, make sure your wires are properly run and routed the correct way and out of sight. Obviously, if you can get them to the backbone or behind a shroud or something that would be the best bet. So double-check and make sure all these suckers are out of the way.

And if you have a stock set up even better, always pretty good about having all that stuff already done. But those longer-term rides, you never know what might be coming loose and getting out of the way. So double-check that. I need to check this chat box. You love your wires, don't you, Zach?

Oh, yeah. They don't break down at all. Cool, cool, cool. So guys, I'm just waiting for the good old computer to get caught up here. We got a guest here, I got an 07 Fatboy, I get rattling sound in fifth gear that sounds like something coming from the drive train.

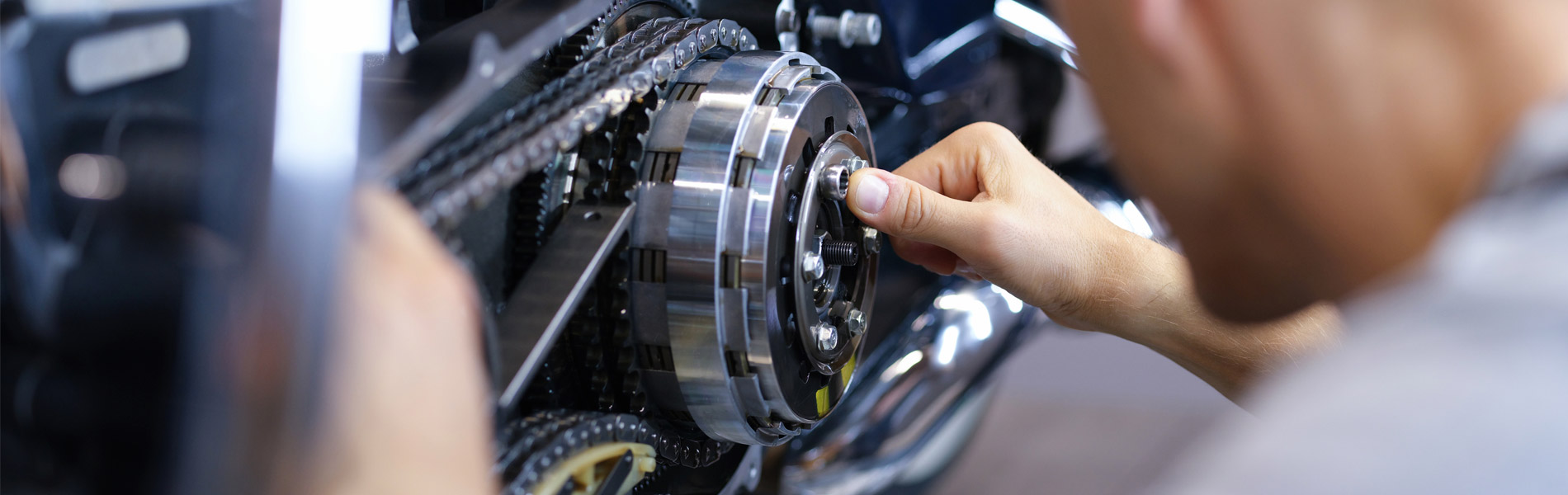

Not sure if it's the compensator or the transmission. My recommendation is that you get in fifth gear then you might have some dog legs that are worn out. And if you definitely, if you have miles on there those shifter forks and those dog legs will wear out time to time. But what I'd suggest on that with an 07 Fatboy, the less time consuming thing to do is to actually just pull off that primary and take a peak to see if it is a compensator. Those have time to time, they can come loose.

So make sure that knot is fully torqued down to spec. Take a look at the clutch basket as well. And while I've seen weird things that fourth or fifth gear something will react differently. So take a peek at that and see if that, or the chain is doing anything before you dive right into the transmission. You can just pull off that top drum cover and from there, you know, shift rate through the gears and you should be able to hear some kind of engagement where it may be going wrong.

So that's my recommendation. First, take a peak and pull off that drive and run through that to see if anything's going haywire in there. Hopefully that helps. Hopefully that helps for you. I don't think I've done this much talking before in my life.

All right, we're gonna continue to pop on. We've been flying through this, flying through time here and I wanna make sure we get this all in with you. So additionally... I'm gonna jump on this side. Depending on the make and model front motor mount, we wanna double check that stabilizers and we wanna go through and make sure those nuts are very not where you have it adjusted, those are all tightened down.

Same thing with the actual amounts for themselves. This model, we're just gonna double-check to make sure that this air scoop is tight from the back and then go through and check out our exhaust. Now, again, I'm gonna reiterate, this is something that you can do after, you know, 5,000, 10,000 miles on your bike is to take this big look in. It's not necessarily something you should do, you know, right out of the get go, unless you really like tooling around and tinkering on your ride. So suggestion obviously would be, we've talked about this, air intake, no matter if it's OEM or aftermarket, go through and make sure everything's tightened down on there, you know obviously probably need to swap out that filter or clean it, so while you're in there make sure everything's tightened down and looking good.

Even go through and make sure your exhaust stud nuts right there are tightened down. Any brackets that you have with these guys, which we've got a torque clip back here. We'd wanna make sure additionally with our bracket going through our bottom of our down tube there. So make sure those are all tightened up and most importantly make sure those heat shields are tightened up as well. I know just like the terminals on the battery, it's easy to pull out a flat head and try doing that, you're gonna strip it out.

You're gonna miss it potentially and start scraping that chrome. Get a socket, take the time to get a socket and go through and crank those down to make sure you have proper torque on those and those are seated well. Floorboards, chatted about this one a little bit earlier, make sure these guys are all the way tightened down. If you have bushings in there or some kind of rubber isolator in there, make sure those are tightened down and starting to come out with those. Now, that lever, it's our brake lever, make sure this is all locked down and same thing with our reservoir.

So we'll be going through that and working our way backwards. Oil lines, another big area that we wanna double check and make sure that if you have actual clamps on there requiring just like a heat shield clamp right here and make sure those are tightened down and there's not any play on that. Also make sure they're all the way pushed up on the fitting. If you find a loose one, make sure you loosen it up re-put that on that fitting and make sure it's fully sealed and then tighten it back down. So you'll be amazed at how well these bikes can really cause us big time headaches if we don't take those kinds of measures.

So again, check those oil lines. You can check them for any kind of abrasions or cuts too, if you have like a stainless cover or a hose like this and just run your finger through them and see if you have any leaks as well. Sensors, we wanna take a look on those with our exhaust system, we're gonna look at the front end the rear and make sure those are fully sealed still. And if they're not obviously tighten those up and then look at the connections for those as well. So go all the way back on street glides.

It's gonna be on your right side shroud, make sure those are fully seated as well. Woo, man. So oil lines, temperature gauges, and then we actually have, I just saw this with the swing arm, there's a cap that's pushed off right here. So we're gonna have to double check that, another thing. So it's time and time again with our swing arms on Softtail models, what we have is we have a splash pan back here and then we have our pivot arm going through with two bolts and a combination of washers and bolts in there.

And on the outside of those, if we don't have a fully seated bolt going into their swing arm here, we have a cover. This one's pinched, so I actually can't pull it out right now. But what we do with those is you will have an Allen that's a set screw to hold that in there on the outside or outside of the actual cover that goes all the way through. But we also silicone them in there too that bring a second barrier for it to fall in off. So double-check these, if you do have a Softtail model and make sure those are fully seated, those little Allens just gonna be a pain in the rear half of the time, so double check that as well.

Rear floor pegs, if your old lady is out there cruising with you time after time or whatever the scenario is, check those out and make sure those are still obviously number one, they're folding correctly and coming back in. Time and time again, you'll see that these will come loose if you're putting a lot of pressure on them. And just making sure there's no cracks or any stress fractures with those and you'll be good to go on that side. Flanges aren't something that, you know, are the big things to come loose but obviously it wouldn't hurt to run through these and look at 'em. And same thing with your rear fender bolts, make sure those are all mounted still securely and just give a good torque on these guys.

Now, before... I'm gonna jump into the thread lockers here shortly but make sure these are all using blue thread locker. And that's a must on those. Bikes with saddlebags, we wanna make sure obviously number one that it's mounted correctly and still not coming loose. This was actually a bike, the owner had issues coming out of a Harley dealership and the bag came off because of the locking mechanism then sure enough once we got our hands on to it, it decided to re-erect and come back at it and test drove it when the bike was done and the bag flew off again.

So those locking mechanisms in there, you know, if it's even a click off, will disengage and you'll be looking at a $1,000 re-do on the leather and the Cayman. So double-check those. Also the hinges, making sure those all looking pretty and nice still and you'll be good to go. And then license plate bolts. We've covered that a little bit earlier making sure these are still secure, turn signals in the back whether they're mounted externally or internally on a fender, make sure those wires are still routed correctly in that also those are still snug on those mounting points.

Rear bar and even the pillion pad, make sure those again are mounted. And these pillion pads, I haven't seen one personally come loose into our shop but make sure that these are still snug again and that our mounting brackets down here and again with our polyurethane bushings down here that it's still seated correctly. And you'll see some wear and tear on these polyurethane urethane bushings after you've been out there riding for a few thousand miles on 'em and putting pressure against us. So it's nothing out of the norm but something to just take a look at the same time too. And then seat mounting bolts, God, this is a pain.

So a lot of times we'll have our street glides, road glides, you're gonna have one mounting nut or bolt here in the back. And of course Harley is gonna make it so it's gonna be the hardest nut and bolt to get to without having to try sticking and Allen down there and then potentially chipping the paint. I think they purposely had to put something in there to knock us off our rockers for a little bit. Make sure this thing is tightened. And the setup that we have is actually seat goes on, front two mounts are here, and then the backseat is one point here.

But we actually had a customer last summer who came back around because he was riding and riding and his pillion pad flew off because the bolt came loose and his thing which was holding it in just disengaged and it flew off. So it's stupid stuff like that that seems to be super simple. And yeah, it's fine that it won't cause that headache again. So hopefully you guys are getting that a lot of these areas on the bike. It's very easy to go through and just check a fastener, even by the eye or touch, make sure things are tight and go through that because it can be a world of hurt on your pocket and also your time with riding that they're not checked.

So keep an eye on that. And then before I jump into the thread locker... Jeez, we're scooting. Before I jump into the thread locker we're gonna go through under the seat here and what we have. So with this model, we've got our ECU this is the motherboard of our bike.

And then obviously all our looms of wiring coming back here to our connections, our fuse, our main fuse right here. This is the data bus that we'd put a tuner into back here. But making sure that all these are still properly routed the correct way. All it takes is for one loom to pop up on top of this frame rail. That's why they have these as well, where these are actually metals, where the seat can sit down and not bind and kink, these wires, excuse me.

But make sure those are all still in place. You can use a couple zip ties. You don't have to use a million zip ties to put the things down, but just use a few to make sure they're still in place and that you don't bind and kink those. Eventually we should do a video on just showing them how to burn up a wire pretty quick. So at the end of it would be a smoke show.

But making sure these are all properly routed and then the fuses are still properly seated in there. And also the ECM is mounted and that the locking mechanism for your connection here is still seated correctly. And while you're down here make sure all the bolts and some of these gas tank bolts are all nailed down and ready to ride another 5,000 10,000 miles wherever you're at. But the last thing on this battery, I would double check and make sure that strap is properly still working on the top here. Pretty much five out of 10 bikes that we get in we'll see those straps are already undone and those cushions are completely...

Those cushions are preventative to make sure that battery doesn't shake and rattle and lose its sturdiness. But those cushions will be completely nailed down and allowing for that battery to move a lot. So make sure you have some kind of a wedge or something in there to make sure it's not wiggling and shaking around while you're rocking down the highway. And then these terminal nuts that we've already discussed a little bit here, make sure those are properly seated, and those connectors are in place and you should be good to go. I think that's a majority of the bike.

Thanks for sticking with me with that long wind. On this side obviously I'm gonna touch real quickly that you're not gonna be able to see just yet but the primary, we wanna look at the Derby cover. If you've got an aftermarket Derby cover on there making sure the seal is still on there. Again this as an enclosed wet primary. So making sure that Derby cover and that seal are still working and sealed up, all the lubricants.

Making sure that outer cover is still intact. And then even one of the most overlooked items I would say is our actual kickstand. So we've had an instance where kickstands have come in and the spring is gone. And what that spring obviously does is it pulls the kickstand back to make sure it's dislodged and letting you ride. If that spring is gone, that kickstand is gonna come down, drag on the right side and make a turn, it's gonna buckle your bike.

So I can't stress enough the safety side to this to making sure that everything is properly working in there. You know, put some anti-seize on it, grease it up whatever you feel is suitable for your application and make sure that is all properly working. And I know it's a pain in the ass to have that spring just get that in there and seated correctly but again, you're gonna avoid some major, major safety stuff and potentially some major damage to your bike if that thing's not done correctly. So take a minute, make sure that kickstand is still working pins down. Your white bushings are in there on both sides are still installed correctly.

And then shifter linkage, we wanna make sure that it's still working properly and those are all together. So Holy cow, thanks guys for sticking with me through that whole thing. I hope you guys find this beneficial because I know after you guys take rides on board with you, five, 10,000 miles, last thing you kind of wanna do is really to take a whole run through your bike, but yet again, you never know what you're gonna find. So make sure you take some time. Hopefully this was helpful and beneficial to get you from A to B or A to Z on on what to check and some of the major things.

And then if you're gonna get a real big tear down over a winter month or something with you guys make sure you're checking bushings, you're checking play and laterally and making sure you don't have too much. So that's a whole different conversation. If you're gonna go internal and make sure all that's going, but that's when you get up there to the 75, 100,000 mile markers up there, and same thing on the engine, so. All right, I promised you I'd cover those thread lockers and we're gonna get onto that real quick. Before we...

Whew. All right, thread lockers. I think people jump over this pretty quickly, but... I got a few things out here for ya. There's time and time again I wish these things weren't magnetic bolts.

I'm pulling up about half an army of nuts and bolts here for you guys. All right, so I'm gonna cover two different things. One of the items that we have, obviously I've got a hex nut or bolt right here and then a flat washer, a split washer. And this one's probably a little bit better to see. Can you see this?

And then just a regular nut. Not a Nyloc, just a regular one. Now, the reason for using Loctite is to obviously hold that bolt into place. And that is usually in turn when you're not using a combination of split washers, Nylocs and flat washers. So if you have something similar to what we have here on the rear fender, where we have a through bolt going through and then a nut on the outer side, what we're gonna do is actually use our bolt.

And we're gonna put a flat washer on, this side, run it through, put a flat washer on again and put that split washer on and then our nut. Now what happens when these all work together is that, the split washer, the reason why it's literally split is it puts pressure against the actual nut and the flat washer preventing it from backing out. Now, what I typically like to do, and what we do at the shop is that we'll put a flat washer, a split washer and then a Nyloc. And the Nyloc you'll see with that clear coating on the outside and that's another preventative. But that's the reason for having that.

And I won't go too in depth because there's videos on this that you guys can check out too. But that's the reason for doing that. So if you're ever gonna put split washers on and avoid the thread lockers, make sure you're doing a split washer and then a Nyloc as well. Now on some of these thread lockers. We have had our fair share of horror stories where we have green lock tight we've had in and that was holding an axle nut on.

And we actually had to bring out the oxy-acetylene torches with a rose button and heat it up. And eventually I think we had to cut it off. But there's four different types of thread lockers. So there's a green there's, which is I'm not of the midway green, you're never gonna get that bolt or nut back off. You have red, which is gonna use some kind of heat to get that back into a liquid form to allow you to pull the bolt out.

You have the blue, which is our most go-to color. And then we have purple which personally, we don't even carry. And we don't care green either. So you're gonna typically use a blue or red. Now we've got two forms here.

We've got the red liquid and then also the red paste. And it doesn't really matter what you're doing here, it's gonna dry the same. But when you're applying the thread locker, here's the other kicker when you use the blue here. So when you're applying it, can you see this? You're just gonna put it at the tip of the fastener right here.

You're not gonna run the entire length of the bolt and the nut down. And the reason being is that once you apply that thread locker right here and you start driving in that faster, it's gonna work its way through all these little grooves and make its way back, and then eventually, you know, dry and secure the fastener altogether. So if you're going from the head of the fastener all the way down to the bottom, that is that's pretty overkill. So don't stress about putting too little on, just put some right here at the tip and take that route. Blue is gonna be your go-to one, red, we only use that really into some areas that we will likely not have to take off that component for a while, or we just frankly don't want that to come loose.

So the swing arm pivot we'll put those bolts in with red Loctite, same thing with a lot of axles. Rear axles, we'll put those in. And then same thing with brake rotors and even sprockets in the rear we'll put those five bolts in into the hub with red Loctite. Now, if you're using Bilic, that's really gonna suck because it's probably not gonna come out. So make sure you use an acceptable material and metal on that one.

And then mounting bolts, you know, engine mounting bolts, transmission bolts, those would be something to red but everything else is blue and that'll be your go-to thing. So let me double check right here before we run out of time. Man, Dennis, you are working, man. I would like to upgrade the carnival car. Would you recommend for an upgrade?

Am I gonna see a big difference in performance? All right, you've got a question is 98 Diner. wide glide with a stock car with jack kit. And we'd like to upgrade the carb. What carb would you recommend for an upgrade?

And will I notice a big difference in performance? Two ends to your question. If you get the right setup with the right exhaust you will notice a big performance increase, but check out some of the videos that we have here on Fix My Hog with referencing the carburetors in different areas to look for. I don't wanna steer you in the wrong direction and say, go with this manufacturer or this one, but you can go with some of the main manufacturers and get just another jet size go to a stage one or stage two, and work with that and do some fine tuning in the internals of the carburetor, meaning replacing some jets and some needles and you can take that approach too. But keep in mind when you're upgrading your carburetor and you're taking in more air and more fuel that way.

We wanna kind of do them in tangent with the exhaust and on the Diner you're not gonna be worried about too much of a tuner but you could add those kinds of components in. So make sure you're working with that as well. I don't wanna go further on that and steer you in the wrong direction. But you can always work with what you have and continue to work and get that tuned in and work on your timing as well. But there's some of the main manufacturers out there make some wicked wicked carbs that you can just smack right on and you'll definitely notice a horsepower and torque increase on that as well.

Well guys, I think I've done enough talking for this month's live event and obviously always a pleasure being here with you guys. Remember if you've got any more questions on what you should do on your pre-ride or continue to, you know, look forward down the road, send us email, put it in the questions box. We'll get around to it and thanks for tuning in for this month. And we'll see you next month.

When you pull a bolt that has thread locker on it, do you bother using a pick to get out all the thread locker, or can you just put a new dab on and reinstall the bolt without worrying about the fact that some old thread locker might be inside the thread?

I have a 97 Heritage Springer, Since I just turned 69 I don't ride near as much as I use to. Question, since I don't put more then 4 or 5 hundred miles a year on her now, how long can I let the oil change go? Using the new synthetic oil does it make much of a difference. Thanks. Tony