FMH LIVE: Harley Charging Systems

Bob LaRosaCheck out August's FMH LIVE with Bob LaRosa. Bob chats with us about charging systems and answers some great questions from our Hoggers. He reviews the proper operation and thoroughly covers testing and troubleshooting. He also covers true stator and rotor style systems from 1970 to date. On top of that, he presents plenty of demo pieces including a rotor with loose magnets and multiple style regulator/rectifiers.

Here are some video links to check out as Bob reviews the charging system:

Motorcycle Battery Maintenance and Overview

How to Diagnose Your Motorcycle Charging System

Motorcycle Starter Problems & Testing Tips

Check out this page to review charging system removal and replacement.

Bob talks about starter Issues - Here's a video.

Hi, I'm Bob LaRosa and welcome to another "Fix My Hog" live event. I wanna as always remind you to please sign up for the newsletter. It's always chock-full of great ideas and upcoming "Fix My Hog" info. Please feel free to join us on Facebook and Instagram. This topic of this live event is going to be charging systems.

Now I know a lot of us even seasoned mechanics and the heartiest of home mechanics cringe when it comes to electrical repairs. In order to to be able to diagnose and correctly repair the charging system or any other electrical component for that matter you've gotta be familiar with how that component or that system works. As always, I like to break down the electrics of the motorcycle into three main categories. One is lighting and accessories. Two is the ignition system and three is the charging system.

The one of the three that has the greatest bearing on the charging system is typically the lighting and the accessories, especially if the motorcycle's over accessorized. And I don't just mean from the factory the way it was built as a production model, but the plethora of add on electrical components that are available nowadays. Whether it be a GPS unit or a higher wattage or amperage radio sound system that can be added to an existing radio or a motorcycle that's built without a radio at all. The battery is indeed a main component of the motorcycle's electrical system. I just wanna touch briefly on it.

It is a big part of the charging system because the charging system, in essence, replenishes the voltage and the amperage that the battery gives out in order to operate the motorcycle. The ignition system's pretty much a fixed system. If the motorcycle cranks and starts, you've got spark. It's a fixed usage. It's gonna use so much voltage, so much amperage.

It's easy to calculate. The lighting system on the other hand, if you just, for example, change your headlamp bulb from a glass sealed style headlamp to a replaceable high floor for the amperage draw of that headlamp will change. Will it go up? Will it go down? It depends whether you're using LEDs or conventional halogens, some of the newer xenon, those bulbs do typically use more power.

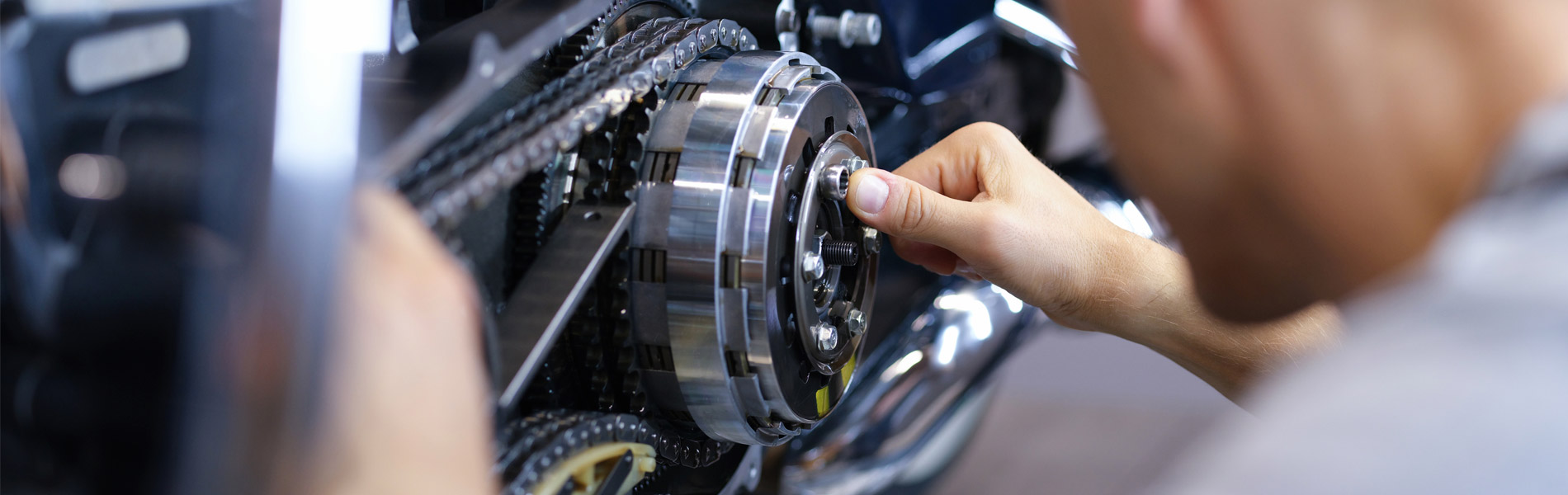

And I'm gonna call it power. The charging system basically consists of three components, the rotor, which is the steel shell with the rare earth magnet. That's literally glued to the outer diameter of the shell. The stator, or stator, the winding of copper, the coil. That magnetic shell the rotor shell rotates around.

Now, the charging system on your Harley Davidson is located on the left side of the engine in the forward most position in the primary, whether it be wet or dry. And the rotor shell is driven off the crank shaft, it's splined to the crank. The stator is mounted stationary behind the rotor shell and then typically found on the front of the motorcycle so it gets a nice flow of fresh air is the voltage regulator rectifier. And when I say regulator rectifier, I know myself some of my earliest school memories, my fondest science memories, you spun the magnet around a coil of wire. The faster you split it with the hand crank the brighter the light bulb, the AC light bulb got.

That is typically what the Harley Davidson charging system consists of. The charging system as a whole typically do not replenish battery voltage at an idle. What I mean by that is, if your motorcycle doesn't have a great amperage draw from other underlying accessories, the motorcycle should be able to recharge at an idle or just above an idle. Most charging system amp power ratings or amp output ratings I should say are rated at a 1,000 RPM. And then again at 2,500 RPM and up.

The reason for that is 1000 is idle, 25 and up, 2,500 RPM and up is considered a running RPM. When it comes to testing the charging system, there's really nothing to be afraid of. It is simple electrics, it is an AC voltage system, at least as far as the stator and rotor go. When the stator's mounted in place, the rotor shell with the rare earth magnet spins around it, creates AC voltage. That's where you'll find the, whether it's two pin or three pin, depending on the style of charging system.

You'll find that plug exiting the crankcase on the left side front and then it'll connect with the voltage regulator rectifier. The AC voltage gets regulated and then it gets rectified and turned into DC voltage, where it's then returned to the battery and replenishes the power it takes to start the motorcycle and keep the motorcycle running. When it comes to testing the charging system there's very few tools that are needed. A good quality voltmeter and a test light is about all I use. There are a number of different ways to test.

There are a number of different ways to test your motorcycle to see what the amp requirements are for your particular application. And the way to do it correctly is with an induction style amp meter or ammeter. And what you really wanna do, you wanna unhook the charging system and then get the motorcycle running and put the inductive lead over the negative cable and see what the motorcycle requires for amperage. What draws from the battery. From there you can determine are you under or overrated.

Most motorcycles built factory production, they leave about three or four amps under what the motorcycle's requirement. The motorcycle only for example, require 28 amps to operate and replenish the battery correctly. In that case, you would have a 32 amp system. Now Harley since 1970, the inception of the cone style cam cover has used a number of different amp output systems, 22, 32, 35, 38, I believe there was a 40 amperage all single phase. When they went three phase, they jumped right up to 38's 45's.

Now I believe there's a 52 or 54 amp output charging system. Big difference between single phase and three phase is that on the stator output wires the AC voltage output wires, on single phase systems there's two wires. On three phase systems there's three. The reason for this, on a single phase system, 22 amp, 32 amp, so on and so forth. The stator itself is one long length of wire in a coil.

When you're testing it, you're testing both ends of the same length of wire just wrapped around a big coil known as the stator. On a three phase system, it's three individual coils of wire that come together and exit the engine at three positions. Again, charging system components are visibly interchangeable but you always need to be cautious that the stator plug and the voltage regulator rectifier plug are matching the same. Obviously they need to plug in to work correctly. When it comes to checking the charging system.

The first thing I always do, and like I said, I'm just gonna touch briefly on the battery because you should take for granted that you have a good battery. When I say good, it should be fully charged, 13, 8 to 14.8 volts and it should be fairly new. I don't let my batteries go beyond four years of age in any of my motorcycles, regardless of how much I ride, regardless of how much they sit. Here in new England, we do have a short riding season. Battery chargers, battery tenders are a must.

The whole battery thing aside, the charging system, in order to check that the charging system's working correctly, first place I head is under the seat, right to the battery. I take my voltmeter, set it to DC volts, whether it's on an open range scale or on a zero to 20 volts DC. Which is what the battery gets replenished with, direct current voltage. I start the motorcycle, I put my volt meter across the battery, red lead to positive, black lead to negative. And I slowly apply some RPM with the throttle obviously.

And what you should be getting is almost instantaneously, you should see that DC voltage getting replenished to the battery. You should see it jump on the scale up to about 14.8, 15, 15.2 volts. And at no time should it overcharge. And in my opinion, that's about 15.5 volts and above. If it does overcharge, you will literally start to boil whether it's an AGM battery or a regular lead style flooded battery.

You'll start to boil the contents of the battery because you're overcharging. At that point the regulator most likely will prove to be defective, it's stuck wide open and not regulating voltage the way it should. That is the regulating side of the regulator rectifier. When it comes to AC output, right off the stator out of the crank case, what I like to use is an old voltage regulator plug that matches the stator. Put my volt meter into the plug, start the motorcycle, set the voltmeter on AC voltage because it's direct AC output at that point, excuse me.

And you should be getting somewhere around 20 volts AC per 1,000 RPM. You give it a little throttle, take it up to 2000. You should be getting 40 volts AC. 3000, you should be getting 60 volts AC out of the stator. Directly out of the front of the left side of the crank case.

When it comes to checking AC voltage output on a three phase system, it is a little bit different because it's three wire. But you're doing basically the same check. You're checking pin one and two for AC voltage output. Should be about 20 per 1,000 RPM. Then you're gonna check pin one and three and then you're gonna check pin two and three.

At that point, you've checked all three windings on a three phase stator, for AC voltage output. Again, all of these tests can be found in great detail in your factory service manual. I want just give you a little bit of confidence, to not be afraid, to do your own diagnosis because you're familiar with how the charging system works. Another test I like to do, is just with a standard test light. I like to unplug the voltage regulator from the stator, put the test light on a good ground, preferably the battery negative terminal, checking on the positive side, make sure the test light illuminates.

And then go right to the pins on the plug of the voltage regulator. Check each one individually. That that test light should not illuminate, if it does, what you are you have the voltage regulator is bleeding back power when the motorcycle's not running and it's just running to ground and it will drain your battery. The voltage regulator at that point the diode that keeps the energy or the power or the voltage amperage from flowing in the incorrect direction is no longer working correctly in the voltage regulator rectifier. And that component needs to be replaced.

Very rarely, I do replace a lot of regulators, but very rarely do I replace just a voltage regulator on an older style system. And when I say older, not necessarily by age, but by mileage also. If I've got a newer bike with 60 or 70,000 on it, I definitely wanna do a little extra testing, a little extra looking around. And a lot of times I'll pull the outer primary just to get a look at how everything looks behind the compensating sprocket. I like replace charging systems all three pieces at once.

Rotor, stator, voltage regulator rectifier. Reason for that is everything starts off the same age, all fresh components, they should last a good long time. The downfall with this type of permanent magnet charging system is that the heat buildup from the stator creating the output power can be great. Especially if you're over with what your maximum amperage draw should be. That stator's working extra hard to keep up when all your accessories are turned on.

So I highly recommend if you do a little math and find out you're right on the fence, as far as amperage. If you've got a 32 amp system and you really should have a 38, and your voltage regulator is giving you trouble, I'd highly recommend buying all three components and upgrading the charging system works less hard to replenish the battery when you're using all your accessories. Radio, GPS, whatever else draw you may have. Lighting is a big factor. It is a big power draw, the big power usage component.

Bear that in mind when you're adding additional passing lamps, running lights, fog lights, you know, LEDs do use a lot less power but I do see a lot of people put a lot of conventional lighting on motorcycles still. And not really realize the detrimental effect that that added amperage draw may have on the charging system. Now, the stator itself, the windings, the copper winding, it's a pretty simple operation. I only, it's basic laws of electricity. You're gonna come across two issues with the stator.

One's gonna be an open, one's gonna be a short. The open obviously, the coil of wire, the length of wire has a break in it somewhere. And that break can also include just the deterioration of the insulation on the copper wire due to being an overheated. Or you're gonna come across a dead short where that length of wire that's in the winding touches directly to ground somewhere along the path. A lot of times it won't just stop putting back input voltage to the battery, but it will decrease it greatly.

And if a charging systems not working a hundred percent and the motorcycles used to be getting ridden on the highway, but yet you happen to get caught in traffic and it depletes the battery voltage, chances are you're gonna have problems with how the motorcycle runs and operates. It may not leave you stranded but it is gonna take its toll on the battery. The starter motor especially if the battery is not a hundred percent fully charged. There are a lot of variables I do come across quite a bit. The rotor shell itself, this is the metal shell.

You can see it's splined to the crank shaft. You can see that the rare earth magnets are glued to the metal shell. What I commonly see most often is those magnets because they're in a bath if oil, because they're subjected to excessive heat over time, the magnets come loose. These magnets slide around, touch each other, charging system output will either be zero or it won't work at all. You know, when I say zero, it's trying to put power back but it can't because it's not working correctly.

You're not creating the correct amount of AC voltage from the permanent rare earth magnet spinning around the copper coil of wire. That is this component. This is mounted permanently or stationary to the crankcase. This is the plug that you'll see comes out of the crank case. These two components work together with a rotational effect and create the AC output that I speak of.

Like I mentioned before, there is a multitude of different style connectors used for the Harley Davidson charging system. And again, be aware when you're working on your bike what style plug you have on your voltage regulator as opposed to the stator Make sure they're correct. I've got a lot of people try to run a 22 amp voltage regulator or stator with a 32 amp voltage regulator or stator. They may look similar. There are two prong that tells you right off the bat that they're single phase but the problem being they don't correctly plug in and connect to each other.

And again, I like to keep the extra plugs. I like to keep the extra plugs just for testing purposes. For example, this 22 amp, this is an old voltage regulator plug that I use for testing. I plug it right into the stator. I've got my two open ends.

I can put my voltmeter to it, check AC output easily and safely. Yes, I have had people test charging system with regular incandescent light bulbs. You certainly can get the light bulb and a socket configuration, plug it into the stator, start the motorcycle it'll illuminate. The more you give it RPM, the brighter the bulb should get. It's really just telling you that you have AC output.

It's a good field test in a pinch but it's really not good thorough diagnosis and repair of the charging system itself. The main component I should say that fails most often is the regulator rectifier. You can see it's finned. Typically it's found out in the front of the bike where it can get a nice fresh air flow and cool down. But this component is what the AC voltage goes into and comes out of DC current goes back to the battery positive and replenishes the voltage and amperage that the motorcycle utilizes to operate properly.

Nowadays, there is a number of great quality three phase systems that are available for motorcycles from just about just about 1980, 81, 82 and up. You need to shop around. You need to do your homework. I am not a big fan of bigger is better but when it comes to charging systems, I always go with the biggest amp system that I or my customer can afford. I would much rather put in a newer style three phase system for a couple bucks more while we're in there, then have them buy another fancy piece of chrome.

Charging system is very important. It's one of the most important components on the motorcycle because it's what replenishes the battery while the motorcycle's operating and battery voltage is very important. Keeps the bike running, gets you there, gets you home. I touched on a bunch of things. AC output should be about 20 volts AC per 1,000 RPM.

You wanna make sure all your connections are clean and tight to the battery. To where the main output lead wire goes back to the main circuit breaker that feeds the battery. Make sure your breakers in good shape. Make sure important things like the ground, whether your voltage regulator is grounded by mounting to the frame or it has an external ground, make sure both of those ends where they bolt to the bike or where that ground bolts to the frame are always good and clean, grounds are very important. We talked about voltage feedback, the test light.

Grounds on the regulator, it's a very broad topic but there's not a lot when it comes to understanding how it works and knowing that things are working correctly. One thing I do wanna touch base on is the coating, the insulating coating on the stator, your length of copper wire. That typically is good for about 400 degrees, 450 degrees. It starts to really wanna toast up. And what happens there is you'll get the actual wire will start to break down.

The copper winding itself will start to deteriorate from the stator itself, whether it's the wires leading out or it's the wires in the winding itself. What that does in essence is it not only contaminates your clutch fluid which in turn can contaminate your clutch, but it doesn't allow the stator to cool down correctly. If you're constantly overworking a component and I don't care if it's charging system, ignition system, your tire. If you just keep getting your tire too hot and gummy, eventually you wear it out prematurely. Same thing applies with your stator.

So if you go to change your primary fluid, which your charging system does run in the same bathroom oil as your clutch. On a Sportster it would be your clutch and the transmission. On the Big Twin it is just the clutch that the stator and the rotor run in the same bathroom oil. If you go to change your fluid and it has a nasty burnt smell, before you dump in fresh fluid, I would make sure to do a good thorough charging system check. Check that stator with the ohmmeter.

You can just check the two or the three pins coming out of the crankcase with the with the ohmmeter. Check each pin to ground. Make sure that there's no direct grounds which tells you that the stator is shorted or the magnet might've shifted on the rotor shell and touch the stator causing a short. And again, make sure that ohms resistance is very low, should be about a half an ohm, 0.5 ohms resistance in the entire coil of wire. You want little resistance so that the stator can create power the way that it should.

Another big problem with overworking or overheating the stator itself is that it doesn't get a chance to properly cool down. And once that primary fluid or clutch fluid comes to temperature and becomes overheated, it's very difficult to cool back down. If it's a dry clutch and you've got a good flow of fresh air then it really doesn't matter. But if you're running a production style wet clutch and you're running the clutch hard, you're running the charging system hard. You're just beating the hell out of that primary fluid.

So, either you've got to address your role riding style, which few of us are about to do that or you've got to address your undercharging situation which is exactly what it is. Your motorcycle's calling for more power than what it can create and it's a simple enough fix. A lot of people we're afraid to just dive in and replace the rotor and stator. But once you pull the outer primary cover, you get the compensating sprocket right loose, the rest of the system is fairly cut and dry to replace. One quick note, when in 95, way back when now, when they first introduced the first production fuel injection motorcycle.

The 32 amp system wasn't enough to properly operate the fuel pump needed for fuel injection. That's what brought on the onslaught of the 35, 38, then I believe it was the 40 or 42 amp output system. And all they really did was put a bigger magnet on the rotor itself. The stator winding typically remained the same but the rotors shell itself got a heavier magnet. Those typical rotors you're gonna wanna use a specialty tool to get the rotor shell off of the spline portion of the crank.

You'll know because like a 32 amp system, you can typically grab two 90 degree picks and pull it off. The newer, even single phase newer higher amp output systems, the rotor shell is really, really strong. The magnetic pull of that shell is really, really strong. You're gonna need a tool to remove it correctly without causing any damage to any of the components including the rotor shell itself. Again, I can't stress enough.

The torture that the stator itself undergoes creating amperage and voltage output that the motorcycle requires to operate correctly when they're in an underrated condition. When you do the math on your motorcycle for total amperage draw, you've got to leave yourself three, four amps extra from what the charging system's rated for. So if you've got a 32 amp system, and let's say it's putting out 34 amps at 3,200 RPM, your motorcycle shouldn't be using any more than 27, 28 of those available amp output. Do the math, do the research. You know, again, there's a lot of forums.

There's a lot of information out there. I wanna just incite the riot to be able to diagnose and then repair. You need to know how a component works in theory so to say, before you can correctly diagnose, repair or replace it. For the most part, voltage regulators do fail. For the most part, you are about a 60/40 split.

If your bike stops charging, you just go buy a regulator rectifier as an assembly. The finned part of the charging system. Bolt it on, plug it in, in it's about a 60/40 split that it's gonna solve your problems. 40% of the time it won't fix anything, 60% of the times it will. But out of that 60% of the time you gotta make sure that a deteriorated stator or rotor doesn't cause the same issue to rear its ugly head in a short timeframe.

What I mean by that is it'll literally burn out a voltage regulator because it's spiking the regulator because the rotor and stator aren't putting out a nice clean flow of power. Batteries again, must be fully charged before you can do any correct testing. The regulator grounds are very important. And I really wanna try to touch base on as many avenues as I can in the short amount of time I have. There are a number of great three phase systems available.

You always have to watch configuration of the plugs and connectors, never any soldering. Whether it be on the voltage regulator plug or the stator, I've seen people try to repair stators. It's just not a repairable item, it's not feasibly repairable. And all soldering wires does is create greeter resistance and you want as little resistance as possible so that output voltage has a clean path back to the battery. If you are still running a conventional flooded battery with removable caps, which I haven't seen one in quite some time in a Harley now, make sure that the electrolyte level is full.

Take the caps off and check all the cells. If you're running a AGM or a sealed style battery, don't let the age go too long. Again, I only wait about four years at best. And then I used a battery as a test battery. I don't like to depend on an old battery out on a long ride.

Very rarely do charging systems charge at an idle. So you've gotta remember it takes a certain amount of time or mileage to replenish the battery, what it took to start the motorcycle. And if it's idling a lot and the charging system is minimal, the battery will let it literally be in a discharged situation. At that point, you've got to address why the battery's not getting fully replenished or fully recharged each and every time the motorcycle's running or you go riding. That's about all I really have to say about charging systems.

It's a three piece system, it's basically very simple. But again, I do see it strike fear into the heartiest of us. Don't be afraid of it, but understand how it works correctly before you attempt to try to repair it. That's really about all I have with charging systems. I do appreciate you're watching this live event.

As always, stay tuned. "Fix My Hog" has a lot of great ideas. We're gonna be doing a bunch of these. I hope a lot of them strike your interest and make you wanna repair your own bike. Don't forget the newsletter.

Please sign up, follow along with the newsletter and follow along on Facebook and Instagram. "Fix My Hog", it's the only way to know what you're riding and know how to repair it. I'm gonna take a quick moment and then I guess we're gonna get into a few questions and the answers and then we'll wrap up this live event. All right. So, Doug from Pensacola, Florida says he has a 1990 Ultra Classic and having trouble with the charging system.

When I start the bike on the amp gauge it shows 13 amps. When I turn the switch for the headlights it drops to 12. If I use turn signal or brake, the gauge will flicker back and forth. If I turn on the road light on top of everything else the gauge will dropped between eight to 10. I believe the problem is in this stator but how do I find out what amp stator I have?

And what size do I need to put back into this bike? Thanks for the question, Doug, Always great to hear from people from the Sunshine State. The gauge on that fairing, the inner fairing on that 1990 of yours, I believe is a volt gauge. I don't believe you're gonna find an amp gauge or ammeter gauge in the fairing but because in order for that to work correctly, you have to run a heavy cable to get a correct amp or ammeter reading up in the fairing. The volt gauge itself is reading correctly.

Problem with a remote gauge is it's got a long path for the voltage to travel to. So they're typically a volt or volt and a half off. That motorcycle being a 1990, was built with a 32 amp system. And if it is an Ultra, you've got a radio, you've got passing lamps, you've got a lot of accessories. The 32 amp system on a non injected bike was marginal at best in 1990.

I'd highly recommend doing a little research. There's at least two great electrical companies out there. Do a little research on the internet, find yourself. I believe they make a 42 amp three phase system. Go three phase and you'll find that volt gauge will jump up when you start the bike and stay up while the bike is running.

Again, those volt gauges are typically a volt or two off. And, Doug, you do have a 32 amp system that can be, it's 32 amp single phase. Can be upgraded to I believe it's 38 or 42 amp three phase. Just look into it, they're readily available and they're made by great product manufacturers out there. Jamie he says has a 2003 Ultra Classic and his battery cables keep coming loose.

This happens every 100 to 200 miles and the bike shuts down. I've tried split lock washers and Loctite, and neither solved, any suggestions? I appreciate the question and I do encounter this problem quite often. One problem is the configuration of the lug on the battery. The other problem may lie in how the cable themselves are routed.

Let's get to the lug configuration on the battery first. Unless it's a solid lug where the bolt bolts directly into the battery. If it's got that little nut that slides in with the spacer and then the bolt, I don't typically care for them. You can Loctite them night and day. The more components, the more opportunity there is for the component to come loose.

Once it's a little bit loose, it becomes a lot loose. Once it's a little bit loose, it allows corrosion to begin. You start to get that white sulphatian powder and then you've got high resistance. You don't have correct operation. The other issue I see most commonly.

is the way the cables are routed. If the cables aren't long enough or they're not routed correctly and they are pulling in the direction of loose. Once everything comes to temperature, that cable wants to pull downward and it will loosen the hardware going to the battery. So either get a longer cable routed nice and lazy. A lot of times I'll the negative and positive together, coming up the face of the battery and put a tie wrap against the two of them.

That way there, they sort of support each other. And you can pull down on them as you pull down on them, make sure they're routed. Where as you pull down, they're pulling down in the direction of tight or clockwise for that matter. That really should solve your issue. If you've got a multi piece connector going to the battery, the little square nut, a rectangular nut, the spacer or the bolt, get a battery with a solid lug.

Where the bolt directly bolts the cable to the lug of the battery. So, Ricardo from Mexico city, he owns a 1995 Road King and it has been quite a problem trying to start the engine every time. I'm looking at a Harley charging system and issues. I charged my new battery and the engine's running for a while and it starts one or two days later, then nothing, I have to charge the battery again. So when performing this test using the temp lamp it's it does not eliminate when placing the hook to the negative side of the battery and the other extreme to the positive side.

But it does when changing terminals. And when placing the hook of the temp lamp to the positive side of the battery and doing the test of each one of the regulator rectifier terminal the test light illuminates. When I place the hook of the temp lamp to the negative terminal of the battery and test each one of the terminals for the regulator rectifier, the lamp does not illuminate. Does this make sense? And if it does, can you tell me why?

Am I making a mistake or performing this test in the wrong way? I really appreciate your support, Ricardo, Mexico City. Nice to hear from you, Ricardo. 95, again, if it is the first of the injectors, the charging systems were marginal. They were really feeling their oats so to say, creating enough amperage output to run the fuel pump on an injected bike.

If it's not injected and it's carburetted, the 32 amp system that's found in that bike should be more than sufficient. Big question here is, has it ever been replaced? Since 95, we've got a few years have past. That stator winding sitting in that bathroom oil all that time and are you testing? If I'm understanding the question correctly, are you testing the voltage regulator voltage feedback correctly?

Yes and no. You know, that is one of many steps that need to be addressed. What I would start with, hook up the entire charging system correctly, go right to the battery. Start the bike voltmeter on volts DC, the range of zero to 20, give it some gas, couple thousand RPM and see what's getting replenished to the battery. It should be right up to almost 15 volts DC input, almost instantaneously off idle.

If it isn't, if it struggles, if it starts at 12 or 13 and it takes a while to climb, the charging system itself is just worn out. So take your time, do the tests per the service manual or what I explained in this live event. Do them correctly and do your own troubleshooting. Again, the system may just be too old to work too well. And you've gotta watch the age and condition of your battery.

If it's going dead after a couple of days, what I would get in the habit of doing is riding the bike, when you go to park it, unhook the negative. When you go back to riding in a couple of days, hook the negative up and see if the bike starts. That's gonna tell you if you've got a static drain on the battery when the motorcycle's not running. Take your time, go through the test systems, the test sequence. I'm sure you'll find what the problem is.

I don't think it's better than you, Ricardo. Right, and then somebody says something is dragging my battery down. How do I tell if it's a Harley voltage or regulator or starter? He says. I don't know if that's A lot of times starters are the culprit.

They do develop a flat spot in the armature where if you happen to land in that position and park the bike, it will drain the battery. But for the most part, that's not the main reason. If it's stator that you meant, the only way to really know is to do a correct stator test. Do AC output, do ohms resistance, do ohms to ground and then check from there. What is the condition of your clutch fluid if it's a true wet clutch?

If you're getting a burnt smell, that stator winding is deteriorating and breaking down. It's contaminating your fluid. It's not operating problem properly but it's also contaminating your clutch. Depending on the age, you have to be aware. It's been in a bath of oil, many years running hot because it's working, it's doing its job, creating voltage.

A lot of these components are not working to 100% of their capacity. So it's easy to upgrade, especially nowadays, to the newer three-phase systems and a lot of your problems will be behind you for good. Somebody live says I turn my key on to start my in 1991 FXDB and the dash lights go on and then off immediately and have no power. Battery's good. I put a new relay in the, and with the same result.

Well, if you're on a 91 motorcycle, if you're turning on the ignition and you're losing everything, chances are it's not the charging system. Either that or you put the motorcycle away without the battery being replenished, put a battery charger on it. Unhook the negative when you park it. And when you go to ride again, hook the negative up and see if the batteries had a charge on it, how the motorcycle wants to start then. Take your time, isolate each and every component and test as you go.

If I'm gonna lead towards a common culprit, I'm gonna say it's gonna be the main breaker. Chase down and replace the main 30 amp breaker. And it may make all your problems go away. All right, Allie says, on my 2004 Road King battery fuse keeps blowing and when I tried to start the bike, there's nothing and I have a new battery and all the lights work. If you're popping at 50 amp, that main Maxi Fuse, you've got a dead short somewhere.

Commonly on Road Kings, the charging system wires run underneath the frame, come up and into the battery compartment. I do see a lot of them get damaged from speed bumps, curbs, humps in the road. Check your charging system wires. Where they make their path of travel, under the frame and up to the battery. Make sure that you don't have a dead short somewhere along the line.

If you're blowing a 15 amp fuse, you're doing some type of arc welding somewhere along the line. Find out where it's coming from. Don't just keep replacing fuses, they're costly. But what you're doing is you're torturing the component that is shorted out. Take your time, hunt down the problem.

You'll be real proud of yourself when you find it. And I can assure you, it's looking right at you somewhere. And of course we have plenty of videos. We have a links here on "Fix My Hog". All right, so my stator is bad and I bought a new one.

While I was setting torque on the fastener, I broke three and was able to take one off. The other two are in the top of the stator. Well, my first question is if you're breaking off stator hardware, are you using the old hardware? Wait, I'm not done. Oh, I'm sorry.

It's impossible to tick off and try everything for the last two weeks. Can I only use two fasteners on the stator to hold it with a lock nut? Or is it too much pressure on the two fasteners and will it'll will eventually break? Yes. Eventually it will break.

You can't run a stator with only two bolts, instead of four. If in fact you are using the original hardware you shouldn't be, the hardware has been subjected to heat and being torqued once to factory spec. I highly recommend anytime you replace a stator, you replace all the hardware with new. As far as getting those bolts out, can be a little tricky. You've gotta remember, you do have the length of the bolt that's broken off going through the body of the stator.

What you may have to do is sacrifice the stator itself, the new stator, and break it away from the bolts. And then you can get the length to the bolt and get it out of there. But you've gotta use your head, don't make any more damage. Certainly don't start drilling or trying to tap that engine crankcase because if you don't do it correctly, you can destroy it. Then you're looking at replacing the crankcase on the engine.

Step back, collect your thoughts, make a game plan as to how to repair it. Like I said, you may have to sacrifice that new stator, you know, by cutting it away and exposing the length of the broken bolt if there is any at all. If it's broken off clean to the face of the crank case, I'd highly suggest getting a professional machinist involved and having them get a look at how to remove the broken portion of that stator bolt. All right, so Dennis has a 2007 Ultra. Sometimes only reads 11 volts on the gauge.

But will come up to 14 positive after a bit sometimes. Check the output for this stator, I have 19 plus on all three phases. I think it might be a flacky or flaky VR going bad. Battery checks a hundred percent when I'm running on throwing a meter at the battery and it's reading 12 volts when it was 13 plus before starting, which is normal. Running it drops 12 volts.

Sometimes comes up to 14 and that's Dennis. Well, Dennis, it sounds to me like you've got an intermittent charging problem. Again, remote voltage gauges will lose a volt and a half in voltage drop carrying the voltage to the gauge in the inner fairing, not uncommon. But if you're doing a correct voltage DC input to the battery positive and negative, and it's only coming up at 12 volts, you're not getting proper charge input to the battery. You know, the stator itself should put out 20 volts AC per 1,000 RPM.

The battery should be getting between 13.8 and 14.8 volts DC, right back to the battery, especially on a later model like that, just off idle. That motorcycle should be almost up to 15 volts DC right off the bat. And it sounds like you may have an intermittent problem. It sounds like you might have a looser corroded ground wire off the voltage regulator. Sounds like you may have a looser corroded connection between the voltage regulator and the stator plug.

Watch your wire, your input wire, back to the battery. Watch its proper routing. Watch that it's not chafed anywhere. A lot of times it won't go dead short but it will not give you a hundred percent voltage input back to the battery. I'm sorry, Gary not Dennis with the possible charging problem.

Anyways, Gar, you gotta do some research. Don't trust, I shouldn't say don't trust. Don't live or die by that voltage gauge in the fairing, always go directly to the battery with a good volt meter. DC voltage, zero to 20 range. Make sure it's getting 13.8 to 14.8 volts DC input right back to the battery right off the bat.

If not, take your time. Do some diagnosis, make sure your battery connections are clean. Make sure your ground connections are clean. Not only to the battery, but to the motorcycle frame. Make sure the voltage regulator is grounded.

A lot of times I'll just run a heavy gauge jumper wire right from the body of the voltage regulator or where the voltage regular bolts right to the negative on the battery, then do your test. Don't be afraid, you can't get a lot of trouble, but know what you're doing before you begin to test anything. It's very important and I know it sounds cliche but you need to know how something operates before you can repair it or diagnose it correctly. The charging system itself may seem like a big mystery but it's really not. It's a very simple permanent magnet alternating charging system.

It is an alternator. If we all remember the generators used to hang out the front of the engines before 1970. The new style three piece rotor, stator and regulator are by far superior. The generators had their place in their day and age, but I can assure you this style charging system works much better. Make sure thing components aren't too old that you're not expecting too much out of them.

You know, if you've got a 20 or 25 year old charging system, you just can't expect maximum output of what the output readings in the service manual or information found online. You can't expect it to be the same because components do diminish by age and by wear. I hope this has been informative. As always I hope it's been helpful. "Fix My Hog" has built a reputation of allowing us to not only understand how our motorcycles, our Harley Davidson's specifically operate but how we can make them operate better and keep them maintained and operating correctly.

I'm Bob LaRosa for "Fix My Hog". Thanks so much for watching. I wanna again, remind you the newsletter, please sign up for it. Keeps you right up to speed on new topics, upcoming events. I wanna encourage you to join us on Facebook, Instagram and that's about it.

Charging systems, not a lot to them. Don't be afraid of them Hunker down, learn a little bit before you dive right in. You'll be so grateful, so proud of yourself when you find the loose connection or the pinched wire or you pull your stator out and find that it just crumbles in your hand. You'll be smelling burnt copper wire but you'll be proud of yourself. You're able to diagnose and repair it yourself.

Again, I'm Bob LaRosa for "Fix My Hog". Thanks so much for watching.

Share tips, start a discussion or ask other students a question. If you have a question for an expert, please click here.

Already a member? Sign in

No Responses to “FMH LIVE: Harley Charging Systems”